What Is Sheet Metal Welding?

Welding sheet metal is a process of joining two or more thin pieces of metal, usually characterized as having a thickness between 0.5 mm and 6 mm by the application of heat, pressure, or both. The procedure results in the metal pieces being bonded together in a permanent, molecular bond, making one, continuous part. The process of fabrication is central to many steel fabrication industries such as automotive manufacturing, aerospace engineering, consumer electronics, construction, and HVAC systems.

The main goal of sheet metal welding is to get a strong durable joint without sacrificing the integrity of the thin metal parent material. The main issue is heat management. Thin sheet metal is very vulnerable to heat-related defects unlike thicker plates of metal that can absorb and dissipate a lot of thermal energy. Too much or improperly controlled heat may cause warping, metal distortion, burn-through (the weld puddle melts a hole in the metal), and a loss of the mechanical properties of the material, including its strength and corrosion resistance.

Thus, effective sheet metal welding is an art of accuracy. It requires a good knowledge of the material to be work metal, the choice of a suitable welding process and the careful use of methods aimed at regulating the heat input and producing a perfect final product. This tutorial will give a step-by-step introduction to the procedures, supplies and professional methods needed to produce professional quality work.

Common Types of Sheet Metal Welding Processes

The selection of a welding process is the most critical decision in a sheet metal project. Each method offers a unique balance of speed, precision, cost, and applicability to different materials and thicknesses.

| Welding Process | Welding Speed | Difficulty to Learn | Equipment Cost | Appearance Quality | Suitable Materials | Suitable Material Thicknesses | Final Effect | Heat Affected Zone (HAZ) |

| MIG Welding | Fast | Medium | $$ | Good | Carbon Steel, Stainless Steel, Aluminum | 0.5mm – 12mm | Stable, uniform welds | Small |

| TIG Welding | Slow | Difficult | $$$ | Excellent | Stainless Steel, Aluminum, Copper | 0.5mm – 6mm | Superior, fine welds | Very Small |

| Resistance Welding | Very Fast | Easy | $$$ | Fair | Carbon Steel | 0.5mm – 3mm | Strong weld points, appearance not as good | Medium |

| PlasmaArc Welding | Fast | Medium | $$$ | Excellent | Stainless Steel, Aluminum | 1mm – 12mm | High precision, clean welds | Small |

| Stick Welding | Medium | Easy | $ | Fair | Carbon Steel, Cast Iron | 2mm – 25mm | Rough welds, typically for repairs | Large |

| Electron Beam and Laser Welding | Very Fast | Difficult | $$$$ | Excellent | High Alloy Steel, Titanium Alloys | 1mm – 5mm | Extremely precise, beautiful welds | Very Small |

| Gas Welding | Medium | Easy | $$ | Fair | Carbon Steel, Cast Iron | 2mm – 25mm | Rough welds, low cost | Large |

MIG Welding

Metal Inert Gas (MIG) welding, also referred to as Gas Metal Arc Welding (GMAW), is one of the most popular methods of sheet metal welding because of its speed and relative simplicity. It involves a continuous solid wire electrode that moves through a welding gun. A shielding gas, either inert or active, usually a mixture of argon and carbon dioxide, is used to flow out of the gun to cover the molten weld pool against atmospheric contamination. Since the continuous solid wire feed is automatic, the operator is free to concentrate on gun position and travel speed, and it is very efficient on long, continuous welds. It is flexible and works well on carbon steel, stainless steel and aluminum.

TIG Welding

Tungsten Inert Gas welding (TIG) or Gas Tungsten Arc Welding (GTAW) is a welding process that is worshipped in terms of its precision and the quality of clean welds it creates. In this technique, the arc is formed with a non-consumable tungsten electrode. The joint is filled with a separate, hand-fed filler material (filler rod). It is time-consuming and needs a great level of operator skill to hold the torch in one hand and the filler rod in the other. Nevertheless, it provides better control of heat input, and is the method of choice when dealing with very thin materials, cosmetically sensitive joints, and non-ferrous metals such as aluminum and magnesium.

Resistance Welding

Resistance Welding, especially Resistance Spot Welding (RSW), is a prevailing process in mass production, like the automotive industry. It entails the flow of a high electric current between two or more metal sheets that overlap. The contact resistance of this current produces a lot of heat, which melts the metal and creates a weld nugget. It is very rapid, with a fraction of a second per weld, automated, and does not need filler metals or shielding gases. It is mainly used to join overlapping sheets at particular points (spots) as opposed to forming continuous seams.

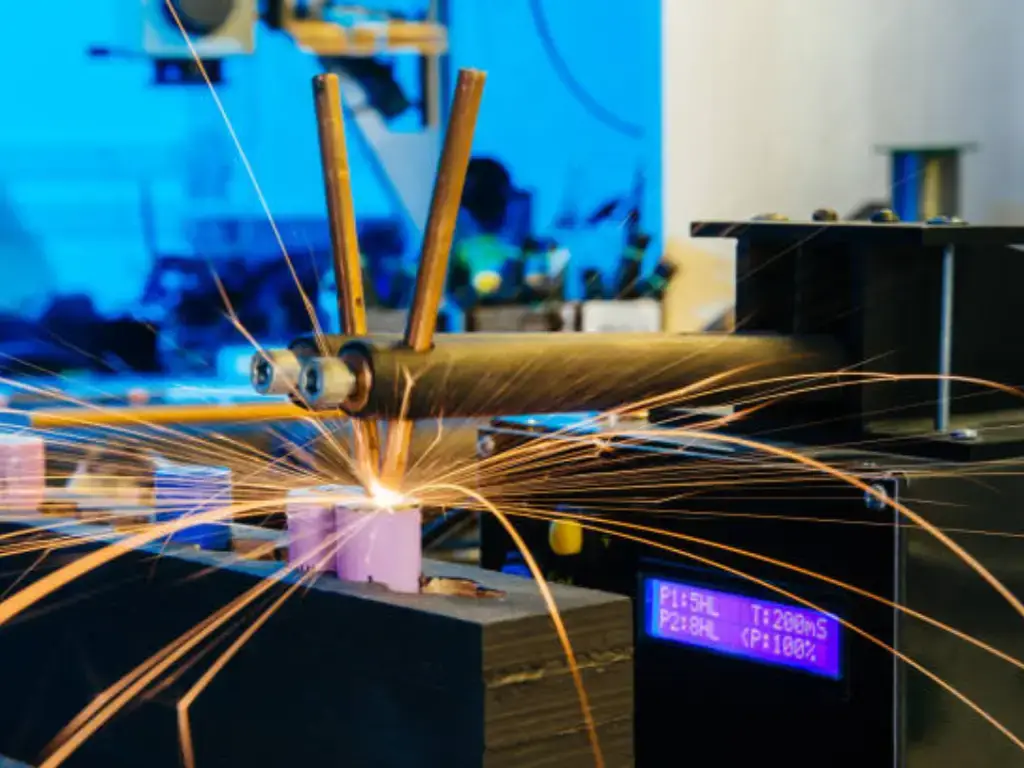

Plasma Arc Welding

Plasma Arc Welding (PAW) is a sophisticated form of TIG welding. It employs a constricted arc that is forced through a small nozzle to produce a high velocity, highly hot stream of plasma. This concentrated energy enables it to weld at higher speeds and deeper penetration as compared to TIG welding. It is very good at welding very thin to moderately thick sheet metal with little distortion. It finds application in high precision work in the aerospace and medical sectors due to its stable arc and high quality of weld. The equipment is more complicated and costly than TIG systems.

Stick Welding

Shielded Metal Arc Welding (SMAW), also known as Stick Welding, is not usually suggested on thin gauge sheet metal. A consumable electrode (a stick or rod) covered with flux is used in the process, producing both the shielding gas and a slag layer to cover the weld. It is, however, not usually suitable for most sheet metal work. The heat input of stick welding is high and hard to control with the precision needed in thin materials. It is very likely to burn through and warp sheet metal severely. It is normally used with thicker materials in repair or field work where portability is a necessity.

Electron Beam and Laser Welding

Laser Beam Welding (LBW) and Electron Beam Welding (EBW) are high precision and high energy processes. EBW joins materials with a focused beam of high-velocity electrons, whereas LBW uses a concentrated beam of light. Both provide a very small, high-intensity heat source, which provides deep penetration and a small heat-affected zone (HAZ). This significantly minimizes distortion, and they are perfect in sensitive, heat-sensitive parts and high-performance applications. The apparatus is costly and needs a very controlled environment(must be done in a vacuum chamber), so it can only be used in specialized industrial applications.

Gas Welding

Oxy-fuel or Gas Welding is an old method that involves melting the parent metal and a filler rod using the flame of the combustion of a fuel gas (such as acetylene) and oxygen. Although it used to be a widespread technique, it has been mostly replaced by arc welding processes in most applications. It has a wide and hard-to-control heat input as opposed to electric arcs, which makes it more prone to distortion. Nevertheless, its low equipment cost and portability continue to find it a niche in certain repair, brazing, and art uses.

Key Metal Types for Sheet Metal Welding

The properties of the base metal dictate the welding parameters, process selection, and potential challenges.

Carbon Steel

Low-carbon steel is the most common material in sheet metal fabrication. It is strong, formable, and relatively inexpensive. It is also the most forgiving metal to weld, compatible with nearly all welding processes, particularly MIG and TIG. Its good thermal conductivity and high melting point make it less prone to burn-through than other metals. The primary consideration is ensuring the material is clean and free of rust or oil before welding to prevent defects.

Stainless Steel

Stainless steel is an alloy prized for its corrosion resistance and aesthetic appearance. It has lower thermal conductivity than carbon steel, meaning heat concentrates at the weld zone, increasing the risk of warping and distortion. Meticulous heat control is paramount. TIG welding is often preferred for its precise heat input and clean finish. Using a tri-mix shielding gas (helium, argon, CO2) and back-purging with argon can protect the back of the weld from oxidation and preserve its corrosion-resistant properties.

Aluminum

Aluminum is a light metal, that is resistant to corrosion and has a very high thermal conductivity. This property together with its low melting point makes it difficult to weld. The heat is quickly lost, and it needs greater heat settings, but the metal may melt through unexpectedly. Moreover, aluminum has a hard refractory oxide film on its surface, which should be completely eliminated just before welding. The AC TIG welding is the most preferred because the alternating current assists in cleaning the oxide layer and the MIG welding with a spool gun is used in faster production.

Copper

Copper and its alloys such as brass are good electrical and thermal conductors. Like aluminum, it has high thermal conductivity, and therefore, it is hard to weld, as high heat is needed. The heat is lost rapidly and preheating is required on thicker areas. The weld pool is also very fluid and out-of-position welding is difficult. The required concentration of heat is usually obtained through TIG welding with a helium-rich shielding gas.

Iron

Steel is more frequently used in sheet metal than wrought iron or cast iron. Cast iron especially is hard to weld because it is brittle and prone to cracking when cooled because of its high carbon content. The welding of iron involves special procedures such as preheating, post-heating, and the application of nickel-based filler rods to suit the lack of ductility of the material.

Surface Factors to Consider When Selecting a Sheet Metal Welding Method

The position and geometry of the weld joint significantly influence the difficulty of the operation and the choice of process.

Flat Surfaces

Flat welding in the flat position (1G for groove welds, 1F for fillet welds) is the easiest orientation. Gravity helps to keep the molten weld pool in the joint, allowing for faster travel speeds and higher deposition rates. Almost any welding process can be used effectively in this position.

Horizontal Curved Surfaces

When welding a horizontal joint on a curved surface, such as a pipe or tank (2G/2F position), the primary challenge is maintaining a consistent torch angle and travel speed as the welder moves around the circumference. Operator skill is paramount. Processes that offer a clear view of the puddle and fine control, like TIG, are highly advantageous.

Vertical Curved Surfaces

In the vertical position (3G/3F), the welder must fight the force of gravity, which pulls the molten metal downward. This requires specific techniques. Welding “vertical-up” (moving from bottom to top) generally produces better penetration as the arc force helps to push the molten metal up and hold it in the joint. Welding “vertical-down” can be done faster but typically results in shallower penetration, suitable only for very thin sheet. Pulsed MIG or TIG processes are effective as they allow the puddle to freeze for a fraction of a second between pulses, preventing it from sagging.

Overhead Surfaces

The overhead position (4G/4F) is the most difficult and hazardous. Gravity actively works to pull the molten weld pool out of the joint and onto the welder. This demands a very high level of skill. The welder must maintain a very small weld pool, use a fast travel speed, and employ a tight arc length. Short-circuit MIG is often favored for its low heat input and ability to quickly solidify the weld metal.

Fillet Welds

A fillet weld is used to join two surfaces at an approximate right angle, such as in a T-joint or a lap joint. The key challenge is achieving proper fusion at the root of the joint without undercutting the vertical member or overlapping on the horizontal member. The torch angle must be precisely maintained, typically at 45 degrees between the two pieces.

Groove Welds

A groove weld is used to join two pieces in the same plane, most commonly in a butt joint. For sheet metal, the pieces are often fitted tightly together (a square groove). The goal is to achieve 100% penetration, meaning the weld metal fuses completely through the thickness of the material for maximum strength, without causing excessive melt-through on the backside.

Expert Tips for Quality Sheet Metal Welds

To get professional-level results when you weld sheet metal, it is necessary to follow the techniques that have been tested.

Apply the Correct Metal Technique: The direction of travel and the angle of the torch are basic. With MIG welding, a push angle is usually used on sheet metal because it gives a less aggressive arc and a clearer view of the joint. In every process, the torch angle should be properly directed to achieve fusion on both sides of the joint.

Choose the Appropriate Filler Metal: The filler metal should be chemically compatible with the base metal to form a strong, sound weld. The diameter of it must be selected according to the thickness of the sheet; the smaller diameter filler melts at a lower energy.

Use Skip Welding Technique: To counteract distortion, weld in short welds, spaced sections. As an example, on a long seam, weld a 2-inch piece at one end, then jump to the middle to weld a 2-inch piece, then to the far end. This spreads the heat more evenly over the part of the metal instead of localizing it.

Use Tack Welding Technique: Prior to laying the final weld bead, make small, temporary tack welds at intervals along the joint. This firmly keeps the pieces in the proper position and does not allow them to move or warp when the heat of the final weld is applied.

Use Small Wire Diameter: In MIG welding, a smaller diameter wire (e.g., 0.023-inch or 0.6mm) is required on sheet metal. It melts at a lower voltage and amperage and can be melted with less heat input and greater control.

Use Small Electrode: In TIG welding, the tungsten electrode is to be matched to the amperage and thickness of the material being welded. A smaller electrode enables a narrower, more precise arc, which is important when working with thin gauges.

Clamp Backing Bar: This can be very effective by clamping a piece of copper or aluminum tightly to the back of the weld joint. These are highly thermally conductive materials and serve as a heat sink, removing excessive heat from the workpiece. This assists in avoiding burn-through and warping, and may be used to form the underside of the weld bead to a smooth finish.

Apply Shielding Gas: The rate of flow of the shielding gas is important. Inadequate flow will not cover the weld against the atmosphere causing porosity. Excessive flow may cause turbulence, which draws air into the weld area. The manufacturer should be followed.

Adjust Heat: This is the most important variable. Whenever you are going to run test beads, always start with a scrap of the same material and thickness. Set the machine amperage (heat) and voltage (MIG arc length) until a smooth consistent bead is produced without burning through.

Maintain Travel Speed and Angle: The travel speed should be maintained to provide a uniform weld bead. Slow movement focuses much heat and can cause burn-through. Excessive speed causes a thin, weak bead with poor fusion. The work angle and travel angle of the torch should also be maintained during the weld.

Choose the Right Company: In cases where the quality of a component is vital, the job must be left to a professional fabrication company. These companies have qualified welding operators, calibrated tools, and strong quality control mechanisms to make sure that all welds are of the required standards.

Common Sheet Metal Welding Challenges and How to Avoid Them

Distortion/Warping: This is the most common issue with welded sheet metal. It is caused by the non-uniform expansion and contraction of the metal during welding.

- Avoidance: use robust clamping, create tack welds to hold the material in place, use a skip welding sequence to distribute heat, use the lowest possible heat setting that still achieves proper fusion, and use heat sinks like copper backing bars.

Burn-Through: This occurs when the heat is too high for the material thickness, creating a hole.

- Avoidance: reduce the welding amperage/voltage, increase travel speed, use a smaller diameter electrode or wire, and ensure a tight fit-up between the metal parts. A backing bar is also an excellent preventative measure.

Lack of Fusion/Penetration: This is a weak weld that has not fully fused with the base material. It is caused by insufficient heat, excessively fast travel speed, or an incorrect torch angle.

- Avoidance: increase the heat setting, slow down the travel speed, and ensure the arc is aimed directly at the root of the joint.

Porosity: This refers to small gas pockets or holes trapped within the weld bead, which significantly weaken the joint.

- Avoidance: ensure adequate penetration shielding gas coverage and the correct flow rate. Thoroughly clean all surfaces of paint, rust, oil, and moisture. Check for drafts that could disturb the gas shield.

Key Considerations in Process and Technology for High-Quality Welds

Achieving professional-grade welds in sheet metal is not about a single tool, but a complete system. While skilled operators are essential, true quality, consistency, and scale are dictated by the integration of superior technology and rigorous process control. This systematic approach separates precision manufacturing from basic fabrication.

Industrial-Grade Equipment

The foundation of a quality weld lies in the capabilities of the machinery. Unlike consumer-grade units, industrial welders provide:

Precise Energy Delivery: Features like pulsed MIG allow for extremely low heat input. This is critical for welding thin materials like aluminum without causing distortion or burn-through. Advanced processes like laser welding, utilized by specialists like TZR, offer superior heat control that is essential for preventing deformation in thin aluminum sheets.

Unwavering Consistency: A high duty cycle ensures stable performance during long production runs, guaranteeing that the first weld and the last are identical in quality.

Rigorous Process Control

Even the best equipment is ineffective without a disciplined process. In a professional environment, this system includes three key pillars:

Verified Procedures: Welding follows a qualified Welding Procedure Specification (WPS) based on calibrated machinery. This eliminates guesswork and ensures repeatable, metallurgically sound results.

Custom Fixtures: Specially designed jigs and fixtures are used to rigidly hold components. They control heat, act as heat sinks, and prevent warping to maintain strict dimensional tolerances.

Traceable Materials: All consumables, from shielding gas to filler metals, are highly pure and fully traceable to ensure the chemical and mechanical integrity of every weld. This comprehensive process control is why leading manufacturers like TZR, backed by teams with over 10 years of experience, consistently achieve high quality products.

The Role of Automation

For high-volume production, robotic welding cells provide the ultimate level of precision. Automation eliminates human variability, executing a perfect weld path every time for flawless consistency at scale.

In essence, this holistic approach—combining advanced equipment with meticulous process and automation—is the bedrock of modern precision manufacturing. It engineers quality into every step, ensuring the final product meets the most stringent standards.

Achieve Precision Sheet Metal Welding with TZR

For projects where precision is not just a goal, but a requirement, partnering with a specialist like TZR provides a distinct advantage. As a leading sheet metal fabrication company, TZR delivers high-precision solutions tailored for industries such as automotive, medical devices, 3D printing, and renewable energy. Our strength lies in transforming complex engineering designs into flawlessly manufactured components using materials like steel, stainless steel, aluminum, copper and brass.

At TZR, we go beyond standard quality expectations. Our commitment to excellence exceeds ISO regulations, implementing rigorous quality control protocols at every stage — from material inspection to final dimensional analysis. With a 98% yield rate, our consistency is a testament to our expertise and advanced technology.

Sheet metal welding presents unique challenges, and TZR is equipped to overcome them with unmatched accuracy and reliability. Choose TZR when your project demands certainty. With us, you don’t just meet specifications — you exceed them. Precision starts here.

Conclusion

Sheet metal welding is a foundational process in modern fabrication. Success hinges on a systematic approach that begins with a clear understanding of the material properties and culminates in the precise execution of the technique. By selecting the appropriate welding process, meticulously preparing the material, and applying proven methods to control heat input, fabricators can overcome the inherent challenges of working with thin materials. Whether performing a manual repair or programming a robotic cell, these principles remain the same. Mastering them is the key to producing strong, clean, and dimensionally accurate welds that meet the highest standards of quality.