Introduction

When designing modern electronics, it is not a choice to control electromagnetic interference (EMI); it is a necessity to be functional and to comply with regulations. Uncontrolled EMI may impair or cause the failure of the performance of a device and disrupt the systems around it. The choice of the right RF shielding materials is thus a serious engineering choice that has a direct influence on the reliability of products, certification and marketability.

This guide offers a methodical approach for engineers to overcome the challenges of material selection, making it the obvious choice for those seeking clarity. It is intended to be a practical guide, shifting between the principles and types of materials to the selection criteria and the frequently neglected part of precision fabrication in the attainment of a successful shielding result.

Understanding RF Shielding Materials

RF shielding material is a type of conductive or magnetic material that is used to prevent or reduce electromagnetic fields. They are designed to provide an electromagnetic shield, isolating delicate electrical circuits and components in electronic devices against external interference or to ensure that a device does not produce too much EMI into its surroundings. This obstacle acts as a Faraday cage, a cage that reflects and takes in electromagnetic energy. The efficiency of this barrier does not only rely on the properties of the material but also on the shape, use and incorporation into the total product design. The full appreciation of these materials is in the understanding that they are not a separate element, but rather a component of a system-wide electromagnetic compatibility (EMC) approach.

A Quick Primer on How RF Shielding Materials Work

RF shielding mechanism is based on two main principles, namely, reflection and absorption. When a conductive surface is exposed to radio frequency waves or other radio waves and electromagnetic waves produced by power lines or even solar flares, a large part of the energy is reflected. The material is highly conductive and this causes an eddy current on the surface of the material and which produces an opposing electromagnetic field that cancels much of the incoming wave. This is the prevailing shielding of most high-frequency EMI.

The rest of the energy that enters the material is liable to absorption. The wave is attenuated as the energy of the wave is converted to heat and dissipated as it passes through the conductive medium. The depth of the material and its skin depth, which is the depth at which the field strength has been reduced to 1/e of its surface value, are the most important factors in determining the extent of absorption. In lower frequency magnetic fields, high magnetic permeability materials are also employed to bend the magnetic flux lines off the sensitive components. An effective shield is one that incorporates these principles. Want to build on this primer with a full guide to RF shielding? Explore it at https://www.tzrmetal.com/rf-shielding/.

Common Types of RF Shielding Materials

The selection of an RF shielding material begins with understanding the available forms and their intended applications. These materials range from flexible films used to address specific gaps to the solid metal structures that form the primary defense against EMI.

Flexible & Gasket Solutions: For Seams, Gaps, and I/O Panels

Even the strongest metal casing can be breached by seams, holes, and I/O panel interfaces. These discontinuities are slot antennas, and the EMI can leak in or out. Gaskets and flexible solutions are designed with the aim of eliminating these weaknesses. Conductive elastomers (usually based on silicone or fluorosilicone elastomers) and wire mesh gaskets, beryllium copper fingerstock and conductive fabrics over foam are all in this category of gasket materials. They are intended to seal openings and provide electrical continuity between a continuous, low-impedance conductive path across mating surfaces, which is critical for maintaining signal integrity. The decision is based on the compression force required, environmental sealing requirements (dust or moisture protection), and the geometry of the interface, and production techniques like FIP gasket dispensing (form-in-place).

Surface Coating Solutions: For Shielding Non-Conductive Housings

When a product enclosure is constructed of a non-conductive material such as plastic due to weight, cost or aesthetics, it does not provide any intrinsic shielding. Conductive paints and coatings are a solution as they leave a thin metallic layer on the inside surfaces of the housing. Typical finishes are nickel, copper or silver in an acrylic or urethane binder, sprayed or brushed on. These finishes form a thin, conductive shell that, in effect transforms the plastic enclosure into a working Faraday cage. A coating is selected by considering its adhesion to the plastic substrate in question, the surface resistivity (ohms/square) that is needed, and its resistance to abrasion and environmental conditions.

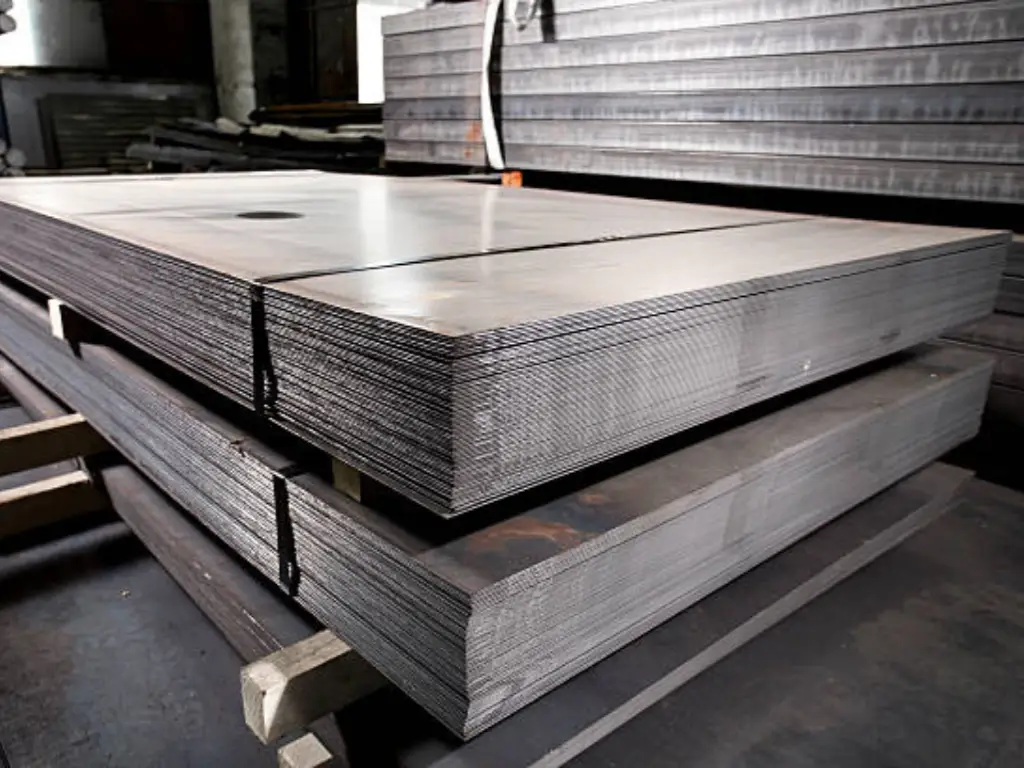

The Structural Foundation: Solid Metal Sheets and Foils

In the majority of high-performance and critical applications, the main shielding structure is made of solid metal sheets. These materials offer a high degree of shielding effectiveness as well as mechanical integrity. The production of these sheets into tailor-made electronic enclosures, brackets, and partitions is the initial step towards the production of efficient RF shields. Selection of metal is an important engineering decision that is made on a trade-off between performance, cost, weight, and manufacturability.

Steel

Rack-mounted equipment, large metal enclosures, and other applications where structural strength and low cost are of primary importance are often made of steel, especially carbon steel and stainless steel. It has a high shielding efficiency, especially with low frequency magnetic fields since it is ferromagnetic. Its major drawbacks, however, are that it is very heavy and prone to corrosion, and may require protective finishes such as zinc or tin plating, to guarantee long-term conductive integrity.

Aluminum

Aluminum is commonly used due to its high conductivity, good strength to weight ratio and easy fabrication. It is a non-ferrous metal, and this is why it is a good shield against high-frequency, plane-wave EMI. Alloys such as 5052 and 6061 are common. Raw aluminum is a good shield, but it quickly develops a non-conductive oxide coating on its surface. A conductive surface finish, e.g. a chromate conversion coating or conductive plating (e.g. tin or nickel), is virtually invariably necessary to provide low-impedance electrical contact at seams and grounding points.

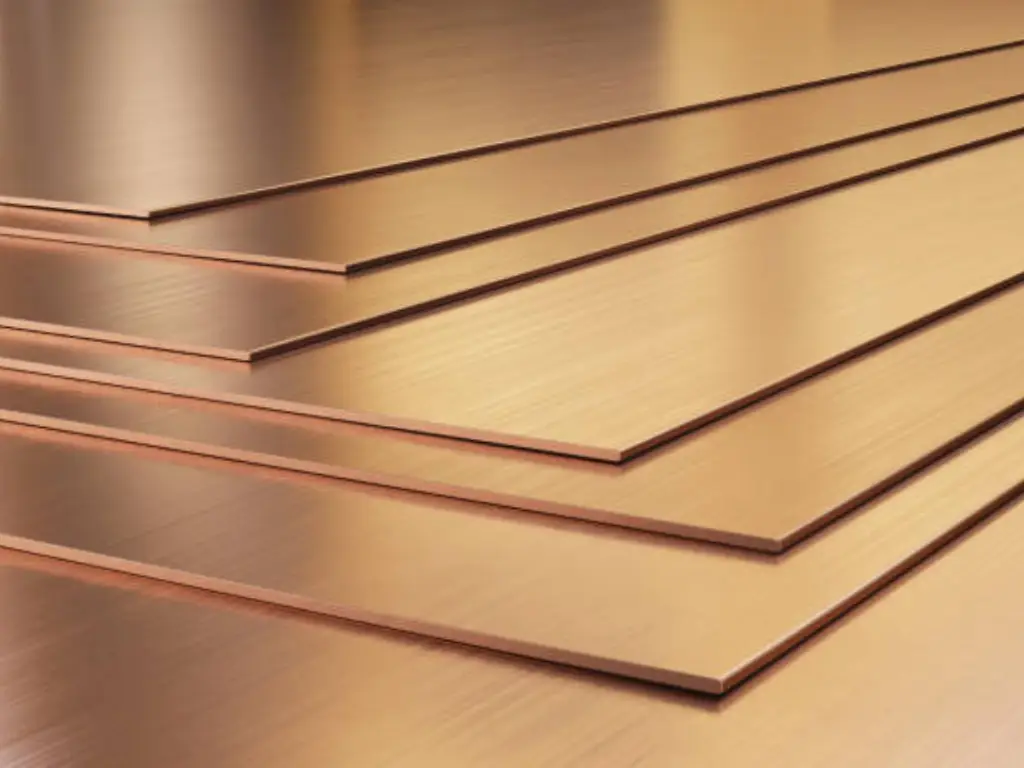

Copper

Copper is the most electrically conductive of common, non-precious metals, and provides the best shielding capability because of the reflection. It is commonly available in foil form at the board level to provide shielding, wrap cable and in applications where maximum performance is needed. Copper is however much heavier and costly compared to aluminum. It is also prone to oxidation, which may reduce its conductivity on its surface over time, making it require protective coating in most applications.

Nickel Silver

Nickel silver is a common board-level shielding material, an alloy of copper, nickel and zinc, commonly used as stamped cans and frames. It contains no actual silver. Its main strengths are that it is very resistant to corrosion and it is very solderable, which makes it easier to attach the shield directly to a printed circuit board (PCB). Its conductivity is not as high as pure copper or aluminum, but it offers adequate shielding capability to isolate individual circuits and components at the source.

| Material Type | Shielding Effectiveness (dB) | Weight (Density) | Cost (Cost Level) | Corrosion Resistance | Fabrication Friendliness |

| Steel | Excellent (Low-frequency shielding, ~80-100 dB) | Heavy (Density: 7.85 g/cm³) | $ | High corrosion rate, requires protective coating (~0.5 mm/year) | Difficult to fabricate, requires extra processing |

| Aluminum | Good (High-frequency shielding, ~40-60 dB) | Light (Density: 2.70 g/cm³) | $$ | Prone to oxidation (corrosion rate: ~0.05 mm/year), needs surface coating | Easy to fabricate, suitable for mass production |

| Copper | Excellent (Superior conductivity, ~90 dB) | Heavy (Density: 8.96 g/cm³) | $$$ | Prone to oxidation (requires protective coating, higher corrosion rate) | Good fabrication properties, but expensive |

| Nickel Silver | Good (Specific circuit isolation, ~60-80 dB) | Moderate (Density: 8.5 g/cm³) | $$$ | Excellent (Strong corrosion resistance, corrosion rate: ~0.01 mm/year) | Easy to fabricate, especially for board-level shielding |

A Look to the Future: Emerging Shielding Materials

Although the standard currently used is traditional metals, materials science is developing the next generation of EMI shielding to be used in applications that require light weight and flexibility. Some of the areas that are closely monitored by R&D engineers include:

- Graphene: a single-atom-thick sheet of carbon that is incredibly strong. Its conductivity and transparency are high, which makes it suitable for ultra-thin and flexible shielding films in wearables, aerospace, and optical components.

- Conductive Polymers: These are conductive plastics, which do not require metallic coating. They provide a light, corrosion-free and easy to mold substitute for complex enclosures and housings.

- MXenes: 2D transition metal carbides/nitrides, a new family of materials that offers exceptional shielding (mainly by absorption). Lab tests indicate that thin MXene films can be used to replace traditional metals such as copper.

Despite the enormous potential of these high-tech materials in the future, the established performance and manufacturability of traditional metal alloys continue to be the standard in the industry in most of the current, scalable applications.

The Engineer’s Checklist: Key Criteria for Material Selection

A systematic approach to material selection requires evaluating several key technical parameters. These criteria form a decision matrix that allows an engineer to balance performance requirements with practical constraints.

Shielding Effectiveness (SE)

The most important performance measure is Shielding Effectiveness, which measures the capability of a material to absorb an electromagnetic field. It is quantified in decibels (dB) and is the logarithmic ratio between the field strength in the absence of the shield and the field strength in the presence of the shield. A 20 dB increase in the SE would be equivalent to a 90 percent decrease in the field strength, 40 dB would be equivalent to a 99 percent decrease, etc. The necessary SE is determined by the application in question, such as the sensitivity of the internal parts and the regulatory emissions limits (e.g., FCC, CISPR). Practically, this value is quantified in a controlled test setup with a signal generator to generate a known RF field and a spectrum analyzer with antennas or near-field probes to accurately measure the difference in field strength.

Frequency Range

There is no shielding material that is equally effective throughout the electromagnetic spectrum. The frequency of the interference is very important in determining the effectiveness of a material. An example is that steel has magnetic characteristics that allow it to be used at low frequencies (kHz range), whereas aluminum has high conductivity, which allows it to be used at high frequencies (MHz and GHz range). To determine the type of material and thickness to use, the engineer should determine the frequency or range of frequencies to be shielded.

Physical Properties

Mechanical and physical properties of a material are usually equally significant as the electrical properties because they define its appropriateness to the desired design and production.

- Conductivity: The greater the electrical conductivity, the greater is the shielding performance by reflection. This is one of the main reasons why copper and aluminum are used in numerous applications.

- Flexibility: Flexibility is a very important requirement in applications where gaskets, wraps, or components are required to conform to irregular surfaces. This is where materials such as conductive fabrics and elastomers shine.

- Thickness: The thickness of the material has a direct effect on shielding, especially by absorption. Densser materials are more attenuating. The thickness choice should be weighed against weight, cost and form factor considerations.

- Corrosion Resistance: The material should be able to retain its conductive characteristics throughout the life of the product. Oxidable or galvanically corrosive materials such as raw aluminum or copper, can be plated or finished to provide long-term, dependable electrical contact at seams and grounding points.

- Adhesion: In the case of tapes and coatings, the capacity to establish a strong, long-lasting bond with the substrate material is the most important. Lack of adhesion may cause delamination and disastrous loss of shielding integrity.

- Weight: In portable, automotive, and aerospace designs, weight is a critical design factor. This is where light materials such as aluminum and conductive coating on plastic substrates are of great benefit compared to the heavy materials such as steel.

Environmental Properties

A material should be capable of sustaining the working environment of the product. This involves high temperature resistance, resistance to humidity, salt spray, exposure to chemicals and mechanical vibration. Material degradation, corrosion and eventual shielding failure can be caused by an environmental mismatch caused by long-term exposure to the environment. To illustrate, a gasket that is designed to be used in an indoor office setting will soon fail in a marine setting.

Beyond Materials: Why Fabrication Quality Determines Shielding Success

The choice of the right material is not the only step. A system is a shield, and the quality of the fabrication and assembly of that system is often the weakest link. A perfectly selected material will not work even when the enclosure it creates is broken by design or manufacturing flaws. Seam gaps, excessive apertures to allow cooling or cables, and improper grounding connections all provide avenues of leakage of EMI that can entirely neutralize the shielding properties of the material used and degrade signal quality.

Shielding theory and mechanical reality intersect at the point of the transformation of a bare piece of metal into a working, closed enclosure. Tolerances, bend radii, weld quality and the accurate use of surface finishes are not trifles; they are the key elements that define the best performance and ultimate shielding efficiency of the product. A poorly made seam may form a slot antenna and a poorly made surface may form a high-impedance ground connection. Thus, the experience of the fabrication partner is as important to the shielding result as the material.

Partnering with TZR for Manufacturability and Shielding Success

As your manufacturing expert and fabrication partner, TZR is more than a metal processor; we collaborate with your design team to ensure your shielding enclosure is optimized for both function and manufacturability from day one. Specializing in materials like steel, aluminum, and copper, we support leading industries from automotive to medical devices.

Our value begins at the crucial design stage. TZR’s dedicated Design for Manufacturability (DfM) team, composed of senior craftsmen, provides rapid analysis of your design. We offer expert recommendations on how to optimize seams, bend radii, and material selection to enhance shielding effectiveness and lower costs.

This strategic input is backed by state-of-the-art execution. Our advanced laser cutting and CNC bending capabilities achieve precision tolerances as tight as ±0.02mm—a physical guarantee of shielding integrity. As your all-in-one solutions provider, we manage the entire workflow, from fabrication to one of our 12 in-house surface finishing options critical for conductivity. Every component is verified through in-process and final inspections to meet ISO standards, assisting you in securing the certifications your product requires.

Have a design ready for review? Submit your CAD files to our team today for a comprehensive manufacturability analysis.

Practical Applications of RF Shielding Materials Across Industries

RF shielding principles are implemented in practically all industries that use electronics.

- Electronics Enclosures: In consumer and commercial electronics, such as network servers and diagnostic medical equipment, custom-made aluminum or steel enclosures are the main shield. They are usually accompanied by conductive gaskets at access panels and I/O ports to provide full system integrity.

- Medical & Healthcare: RF shielding is essential in medical device applications both in patient safety and diagnostic accuracy. It shields very sensitive machines such as EEG and EKG machines against interference that may corrupt data. The most notable one is the MRI (Magnetic Resonance Imaging) room which is, in fact, a room-sized Faraday cage. This shielding helps to avoid distortion of the MRI image by external RF noise and it also helps to contain the strong electromagnetic fields produced by the machine itself.

- Military and Aerospace: Shielding in these sensitive avionics and communications systems is used in mission-critical areas to guard against hostile EMI, and to guarantee TEMPEST compliance to prevent eavesdropping. Applications require high-performance materials and strong fabrication, which may require specialized plating and extensive testing.

- Data Centers & Server Rooms: Data center shielding is done both at the rack and room levels. Individual server racks are also enclosed structures and in high security settings, a room can be enclosed with metal and special doors to avoid data leakage and to prevent external attacks such as electromagnetic pulses (EMP).

- Automotive Electronics: The vehicle of the modern era is a complicated electromagnetic space. Shielding is necessary to ensure the cross-interference and external EMI of sensitive electronic control units (ECUs), infotainment systems, and autonomous driving sensors are not compromised, guaranteeing functionality and safety.

Common Pitfalls to Avoid in Your Shielding Design

- Disregarding Apertures: Shielding can be compromised by any hole or slot in an enclosure. Vents, display windows and cable entry points are antennas that enable leakage of EMI. These should be shielded with proper shielding solutions, including honeycomb vent panels to allow air to flow through, shielded windows with conductive finishes, or terminated shielded cables and connectors.

- Improper Grounding: A shield should be connected to a common ground by a low-impedance path. An improperly installed or damaged ground connection or worse still, no ground connection at all can cause the shield to fail to sink captured EMI energy. This virtually makes the whole enclosure an antenna which usually exacerbates the interference issue.

- Failure to consider Seams and Gaskets: It is a common error to assume that two metal surfaces in simple contact will create an ideal electrical bond. High-impedance paths are formed by microscopic gaps and non-conducting oxide layers. High quality conductive gaskets are needed on all removable panels, lids, and doors to provide a continuous low-impedance seal around the full perimeter.

- Finalizing the PCB Before the Enclosure: It is a fatal mistake to fix the final PCB layout before the mechanical design of the enclosure is thought about. This electronic-first design compels the enclosure to be a compromised box that is built around an object that is fixed, resulting in clumsy location of seams and lack of room to have a solid grounding or gasket. A structure-first design, in which the enclosure is designed in parallel, is inherently more reliable and less expensive.

- Shielding as a General Afterthought: The most expensive error of all is to consider shielding as a last-minute design consideration. Such an attitude results in reactive, patchwork solutions such as the use of foil tapes and ferrites to correct EMC test failures. The only solution to achieving an optimized, reliable, and cost-effective design is to integrate shielding requirements and seek expert design feedback at the very early stages of product development.

Conclusion

RF shielding material selection is a complex engineering procedure that goes way beyond the datasheet. It demands a background in the principles of shielding, a thorough familiarity with the types of materials, and a strict analysis of the performance requirements versus application-specific limitations. Nevertheless, this discussion has revealed that the material itself is not the only half of the coin. The quality and precision of the physical implementation of a shielding strategy determine its ultimate success. The performance of the most sophisticated materials can be easily compromised by flaws in fabrication and assembly. Thus, an effective result is reliant on an organized strategy that integrates material choice with professional fabrication collaboration, converting design will into a conforming and dependable finished product.