Introduction

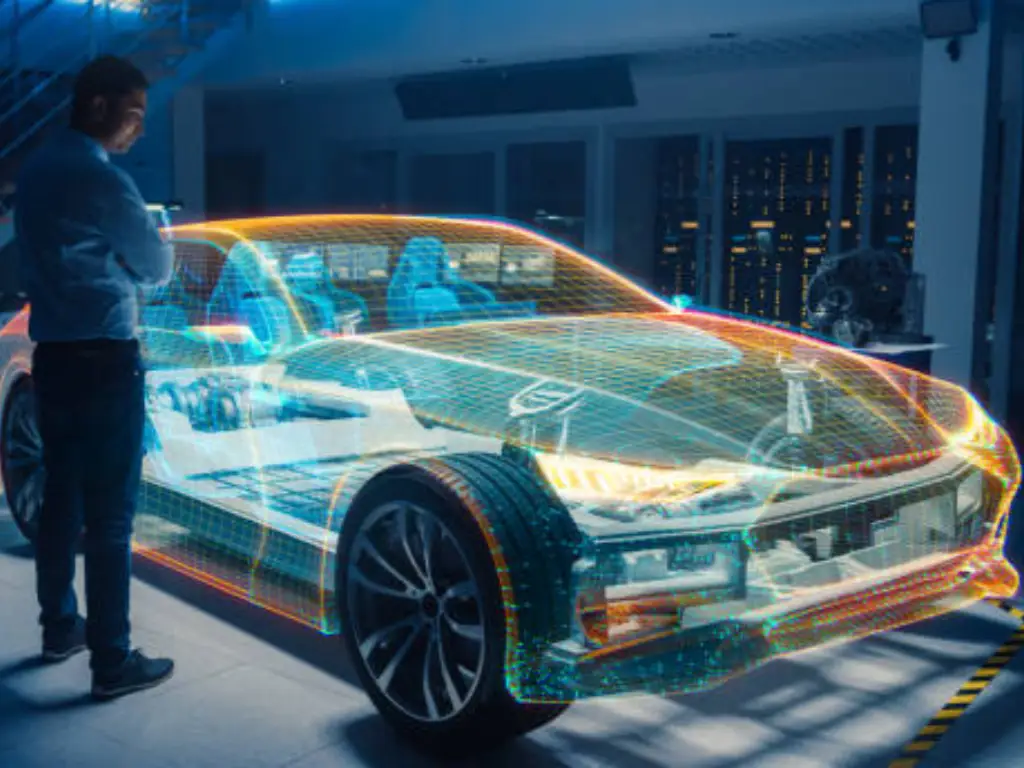

The importance of modern medical technology’s effectiveness depends on the materials used in its devices and implants. Metals occupy an important and distinctive position among these materials used. From internal fixation of fractured bones to the life-sustaining functions of a cardiac pacemaker, metals in the medical industry serve the purpose of strength and durability in medical device applications where there is no room for error. Choosing the right metal to carry out an exercise is an intricate balancing analysis is between the requirements of the human body and the functions of the device.

For engineers, designers, and medical device manufacturers, this guide serves as the first step to understand the foundational principles of medical metals, an extensive categorical analysis of the most common types of materials used, and the importance of meticulously precise fabrication as the bridge between the raw materials and a safe and effective finished product.

Defining “Medical-Grade”: The Core Properties of Medical Metal

The “medical-grade” title is not just a marketing strategy; it means that a material has been validated for a unique set of specifications necessary for a safe and prolonged contact with the human body, ensuring patient safety. For any metal to receive clearance for medical applications, especially medical implants, immediate attention and focus should be placed on these core features. Failure to address these can lead to the device failing, harming the patient, or requiring further surgery. Every medical-grade metal has three basic and definable attributes: biocompatibility, the ability not to corrode, and the right combination of mechanical properties for the intended application. These are essential factors in material selection.

Uncompromised Biocompatibility

For every medical substance, its biocompatibility is a must. It can be explained as the capacity of a material to be in contact with human tissues without provoking any unreasonable or unacceptable localized or systematic reaction. An adequately biocompatible metal must be non-toxic, non-carcinogenic, and non-allergenic to the majority of patients. An implant is introduced and the body’s immune response assesses it as a foreign object. Biocompatible materials will permit a stable interface by either being ignored by the body or encouraging integration. On the other hand, the adverse consequences triggered by a non-biocompatible device can range from chronic inflammation and the formation of a fibrous capsule isolating the device, to the release of toxic ions and systemic degeneration.

Superior Corrosion Resistance

Human beings have a very aggressive internal environment. Bodily fluids are highly corrosive due to the presence of saline chloride ions along with proteins and amino acids. Most metals corrode and are attacked. For a medical device, such a metal needs to be exceptionally resistant to corrosion to be able to withstand such an attack for the entire lifetime of the device, which could be decades of functional use. Loss of corrosion does erode the metal’s structural integrity which could lead to the mechanical failure of the implant. In addition, the process of corrosion unleashes ions into the body which could interfere with some physiological processes. They could also counter the biocompatibility of the device by providing an allergic or toxic counterreaction or corrosion.

Essential Mechanical Properties

In addition to being chemically stable, a medical metal needs to have a particular set of mechanical properties and a good balance of strength compatible with the requirements of its intended use. These properties define how the device provides structural support and behaves under physiological loads and stresses. Key considerations include:

- Strength: This includes tensile strength (resistance to being pulled apart) and, which is of critical importance in orthopedic applications, fatigue resistance (the ability to resist repeated, cyclical loads without failure). A hip or knee joint implant, e.g., has to withstand millions of loading cycles during its lifetime. Fracture toughness is also a critical measure.

- Hardness and Wear Resistance: In the case of articulating surfaces, e.g., joint replacement, the material should be very hard and wear-resistant to avoid the formation of debris particles, which may cause inflammation and result in the loosening of the implant.

- Modulus of Elasticity: This is a property that defines the stiffness of a material. In the case of bone-interfacing implants, it is frequently desirable that the modulus of the metal be similar to that of natural human bones. An implant that is much stiffer may bear excessive physiological load, protecting the surrounding bone against the load it must sustain to be healthy, a phenomenon called stress shielding, and may result in bone loss.

- Ductility: This is the property that defines how a material can be deformed under tensile stress without breaking. Adequate ductility is critical to the fabrication processes and eliminates brittle failure in applications where some plastic deformation is anticipated.

Common Types of Medical Metals and Their In-Depth Applications

The most common alloys used in medicine are dominated by a few materials that have proven to be able to satisfy the demanding criteria mentioned above. These main alloys provide different sets of properties, which make them appropriate for particular sets of specific applications. The typical applications for each are outlined below.

Stainless Steel

The most commonly used metals in the medical field are the austenitic stainless steels, which are 316 and 316L. They are popular due to a good balance of good mechanical strength, sufficient corrosion resistance, and cost-effectiveness. The lower carbon content of the 316L grade (”L” means ”low carbon”) is used in implants because it reduces the chances of corrosion in vivo. Its resistance to corrosion caused by chloride is also improved by the addition of molybdenum.

- Applications: Surgical and dental instruments, temporary fixation devices such as bone screws and plates, and cardiovascular stents are made of stainless steel because of its properties and ease of fabrication. In long-term implants, it has largely been replaced by titanium, but it is still a possible solution in many temporary applications.

Titanium and Its Alloys

Titanium alloys are known to have a high level of biocompatibility and excellent corrosion resistance, which can be explained by the fact that a thin, stable and highly adherent passive oxide layer (TiO2) is formed on their surface. This layer is self-healing and makes the material nearly totally inert in the body. Pure titanium and its alloys are also very strong, with a weight-to-strength ratio and their modulus of elasticity is far closer to bone compared to stainless steel or cobalt-chrome alloys.

- Applications: Titanium and its alloys, including Ti-6Al-4V, are the most common permanent implant materials due to their properties. They find wide orthopedic applications, such as total hip and knee joint replacement, spinal fusion cages, and trauma plates. They also serve as the standard of dental implants because of their capacity to integrate with the bone, the direct structural and functional relationship between living bone and the surface of the implant. It is also used in other applications such as pacemaker casings, drug pump enclosures and artificial heart valve components.

Cobalt-Chrome Alloys

Cobalt-chromium (Co-Cr) alloys are characterized by their remarkable hardness, high strength, and high wear resistance. These properties are sustained even at high temperatures and the material has a high level of resistance to corrosion. This renders it a perfect choice in applications that are characterized by high stress and articulating surfaces.

- Applications: Co-Cr alloys are mainly used in the articulating parts of joint replacements. As an example, a total hip replacement would have the cobalt-chrome as the femur head and the acetabular cup liner because of their resistance to wear caused by millions of steps. They are also applied in dental structures of crowns and bridges and certain designs of cardiovascular stents that need high radial strength.

Aluminum: The Lightweight Choice for Medical Equipment and Housings

Aluminum alloys are essential in the wider medical devices sector, although they are not applicable in internal implants because of the biocompatibility issues of ion release. Their main benefits are low density, about one-third that of steel, and a high strength-to-weight ratio, is the lightweight choice for medical equipment and housings. The secret to its use in clinical practice is anodizing, an electrochemical treatment that forms a hard, inert, and corrosion-resistant ceramic coating of aluminum oxide on the surface. This is a non-reactive, durable and simple to clean and sterilize engineered layer

- Applications: Consequently, anodized aluminum finds wide application in medical equipment enclosures, housings for diagnostic equipment like MRI machines, instrument trays and cases, IV poles, hospital bed components like surgical tables, and mobility aids such as walkers and wheelchairs, where weight reduction without loss of strength is a critical design consideration.

Specialty and Precious Metals

In addition to the three primary categories, there are other metals that play important roles in special medical uses.

- Nitinol (Nickel-Titanium): This is an alloy that has the special characteristics of shape memory and superelasticity. It is capable of being deformed at a certain temperature and then it can be restored to its original shape when heated. It is superelastic and can withstand a lot of strain without being deformed permanently. This is suitable for self-expanding cardiovascular stents, orthodontic archwires that deliver continuous low force, and flexible endoscopic surgical tools.

- Tantalum: This is a dense, very corrosion resistant and biocompatible metal. It is commonly formed in a porous, trabecular form, which resembles the cancellous bone structure, which is a good scaffold on which bone can grow. It is applied in spinal implants, hip replacement acetabular cups, and in the correction of bone defects.

- Precious Metals (Platinum, Gold): Platinum and its alloys are highly electrically conductive and very inert, so they are employed as electrodes in pacemakers, cochlear implants, and neurostimulators. They are also radiopaque (high density), which means that they can be seen on X-rays, and thus can be used as markers on catheters and stents to be placed accurately during surgery.

Key Selection Factors & At-a-Glance Comparison Chart

The selection of the right metal is not a simple task that can be limited to the datasheet. Engineers have to balance the inherent properties of a material with the real-life limitations to come up with the best solution to a particular device.

Factors Beyond the Specs

Although the most important factors are biocompatibility and mechanical performance, there are other factors that have a significant impact on the choice of materials:

- Manufacturability: To what extent can the material be easily converted into its finished form? Stainless steel is usually simple to machine and shape. Titanium, on the other hand is harder to machine because of its high strength and low thermal conductivity. Cobalt-chrome alloys are highly hard and may be hard to work with conventional techniques. These directly affect the cost and time of production.

- Cost: Medical metals have a high cost variance. The most cost-effective is stainless steel, whereas titanium and cobalt-chrome alloys are much more costly. Specialty metals such as tantalum and precious metals are the most expensive. The ultimate price of the device has to be weighed against the performance needs and anticipated life of the product.

- Regulatory Precedent: A material that has a long and successful history of application in other similar medical devices can greatly facilitate the regulatory approval process with regulatory bodies such as the FDA. The process of introducing a new material takes a lot of time and resources to test and demonstrate its safety and efficacy, which is a significant investment.

At-a-Glance Comparison Chart

| Feature | 316L Stainless Steel | Titanium (Ti-6Al-4V) | Cobalt-Chrome (Co-Cr-Mo) |

| Biocompatibility | Good | Excellent | Good |

| Corrosion Resistance | Good | Excellent | Very Good |

| Density (g/cm³) | ~8.0 | ~4.4 | ~8.3 |

| Tensile Strength | Good–Very Good | Excellent | Excellent |

| Modulus of Elasticity | High (~193 GPa) | Moderate (~114 GPa) | Very High (~210 GPa) |

| Wear Resistance | Fair | Poor–Fair | Excellent |

| Relative Cost | $ | $$$ | $$$ |

| Primary Use Case | Instruments, Temporary Fixation | Permanent Implants, Bone-Contact | High-Wear Joints, Dental |

Beyond Material Specs: Why Precision Fabrication is the Critical Next Step

The choice of the optimal medical metal is not the final step. Even the best raw material may be spoiled by a poor fabrication process, or even become hazardous. It is in the process of transforming a sheet or bar of metal into a complete medical part that the potential of the material is either fulfilled or wasted. Precision fabrication does not only concern the attainment of the right shape and size; it is concerned with the maintenance of the inherent characteristics of the material and the end product should not have any defects that may affect its functionality in a clinical environment.

Improper machining may cause residual stresses which change the fatigue life of the metal. Welding methods that are not good may interfere with the passive layer on titanium or sensitize stainless steel, providing locations where corrosion may start. Burrs or scratches on the surface may serve as a starting point for crack propagation or a place where bacteria may grow. Moreover, the inability to keep very high tolerances may result in incorrect assembly, malfunction of the device, or inappropriate fit in the patient. These are the exact specifications that are captured in internationally accepted standards, and organizations such as ASTM and ISO give the final specifications of the material properties as well as the manufacturing procedures of the medical components. Thus, the fabrication quality is as important to the success of the device as the material quality.

TZR: Bringing Medical Metal Designs to Life with Expert Sheet Metal Fabrication

As a leading sheet metal fabrication partner for the medical, automotive, and renewable energy industries, TZR provides comprehensive solutions from design and prototyping to full-scale manufacturing. While we specialize in steel, stainless steel, aluminum, and copper, our expertise allows us to source and process any material to meet your project’s specific requirements.

In the medical sector, we apply this deep knowledge to the precision fabrication of non-implantable components where quality and cleanliness are absolute. Our advanced capabilities—including laser cutting, CNC punching, precision bending, and expert welding—enable us to achieve tolerances as tight as ±0.02mm. With 12 in-house surface finishing options, we ensure every component meets exact functional and aesthetic criteria.

Our commitment to quality is validated by our adherence to ISO 9000-level standards and a 98% product qualification rate. We partner with medical device companies to manufacture components that are a tangible representation of precision and reliability, ensuring your designs are brought to life without compromise. Contact our engineering team to discuss your project, or upload your CAD files for a quote today.

The Future of Medical Metals: A Glimpse into Emerging Trends

Medical metals is a constantly developing field, as it is fuelled by the desire to find materials that have better performance, functionality, and long-term patient outcomes. The future of medical metallurgy is being influenced by several important trends:

- Biodegradable Metals: New metals, mainly magnesium, zinc, and iron alloys, are being developed to be used as temporary implants such as screws, staples, and stents. These materials are meant to support the healing process and then gradually corrode and dissolve, being absorbed by the body. This saves the patient trauma and health care expenses of having to undergo a second operation to remove the implant.

- Additive Manufacturing (3D Printing): Additive technologies such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM) are transforming the production of implants by enabling the production of patient-specific implants with geometries that cannot be produced using conventional technologies. It can also be used to create porous, lattice-like structures that replicate natural bone, promoting osseointegration and enhancing the stability of implants in the long term.

- Advanced Alloys and Surfaces: The development of new alloy systems, including high-entropy alloys, with new combinations of strength, ductility and corrosion resistance is underway. At the same time, more sophisticated surface modification methods are being developed to improve the biocompatibility of the current metals, add antibacterial effects, or regulate the local release of therapeutic agents.

Conclusion

Medical metals selection and fabrication are a very important crossroads of materials science, engineering, and medicine. An effective medical device is the result of a sequence of conscious, well-informed choices, starting with the selection of a material with the desired biocompatibility, corrosion resistance, and mechanical integrity. As this guide has explained, materials such as stainless steel, titanium, and cobalt-chrome all provide a unique profile of properties that can be used to match particular clinical requirements. Nevertheless, the performance of these high-technology materials depends on a production process that respects their specifications. The final step is precision fabrication which transforms a better design into a safe, reliable and effective medical product that can improve, and in many cases save, human lives.