Introduction

Modern electronics has been characterized by two unremitting trends: the growth of computational power and the reduction of physical size. This trend of increased power density in compact form factors has a direct and inevitable physical effect, which is the heat generation of large amounts of waste heat. Control of this thermal output is no longer a secondary consideration but a major engineering discipline, now known as thermal management engineering. Poor thermal management has a direct impact on performance, reduces the life of operation, and may cause system failure.

This guide to the thermal management of electronics offers a detailed analysis of the underlying principles, the basic techniques, the necessary materials and the most important design procedures that are needed to design efficient and reliable electronic systems.

What Is Electronics Thermal Management and Why Does It Matter

The field of electronic thermal management is the engineering of the heat produced by electronic equipment to ensure that the temperature of the components does not exceed the operational limits of the components. It is the methodical study of heat production and the development and execution of systems to remove the heat off the delicate parts and dispose it to the surrounding air.

The physical constraints of semiconductor materials are the basis of the need for this discipline. The operating temperature of virtually all electronic components, including microprocessors and GPUs, power transistors and LEDs, is negatively proportional to their operating temperature.

The inability to cope with excessive heat leads to a number of different adverse consequences. The first is the most immediate, which is performance degradation, also referred to as thermal throttling. When a component like a CPU hits a predetermined thermal limit, its internal logic will slow down the clock speed and voltage to lower power usage and heat production, which directly decreases its computing performance.

The long-term use of high temperatures causes a drastic decrease in the life of the components and can compromise system reliability. The electromigration rate and other diffusion-based degradation processes in semiconductors increase exponentially with temperature, which is explained by the Arrhenius equation. This implies that a small rise of 10°C in the operating temperature can halve or even lessen the Mean Time Between Failures (MTBF) of a component. Capacitors, batteries and solder joints are also prone to premature failure when exposed to high thermal and mechanical stress. In extreme cases, poor thermal management may result in catastrophic failure due to thermal runaway, a positive feedback mechanism whereby an increase in temperature results in an increase in current and heat, and the destruction of permanent components.

Understanding the Fundamentals: The Three Modes of Heat Transfer

A proper use of the three basic mechanisms of heat transfer conduction, convection, and radiation is the foundation of an effective thermal management strategy.

Conduction

Conduction is the movement of thermal energy by direct contact of molecules within a material or between substances in direct contact. Heat is conducted out of a high temperature area to a low temperature area. The thermal conductivity (k) of a material is a measure of the efficiency of this process in watts per meter-Kelvin (W/m·K). Good conductors are materials that have high thermal conductivity, including copper (k ≈ 400 W/m·K) and aluminum (k ≈ 200 W/m·K), which are used to conduct heat effectively. Low thermal conductivity materials, including air (k ≈ 0.026 W/m·K) and plastics, are insulators.

Convection

Convection refers to the movement of heat by the bulk movement of a fluid, either a gas or a liquid. The fluid that is close to a hot surface is heated and thus expands, becomes less dense, and rises. The denser fluid flows in to replace it, forming a continuous circulation pattern. This is referred to as natural convection. An external force, e.g. a fan or a pump, can be used to transfer the fluid across the hot surface to increase the rate of heat transfer. This is referred to as forced convection and it is one of the key principles in active cooling systems.

Radiation

Radiation refers to the movement of heat by use of electromagnetic waves. Everything that has a temperature higher than absolute zero releases thermal energy in this form. Radiation does not need a medium to transfer as compared to conduction and convection and can take place in a vacuum. The Stefan-Boltzmann law controls the rate of heat transfer by radiation, stating that the amount of energy radiated is proportional to the fourth power of the absolute temperature of the object and its surface emissivity. Emissivity is a quantity that measures the capacity of a surface to emit thermal energy with a range of 0 to 1. Dark and matte surfaces are generally more emissive than bright and reflective surfaces.

Core Thermal Management Methods and Components

Thermal management solutions are broadly categorized into passive, active, and advanced liquid cooling systems, each employing different components and principles.

Passive Cooling Solutions

Passive cooling systems do not require extra power to cool down. They are appreciated due to their dependability, ease and zero noise production.

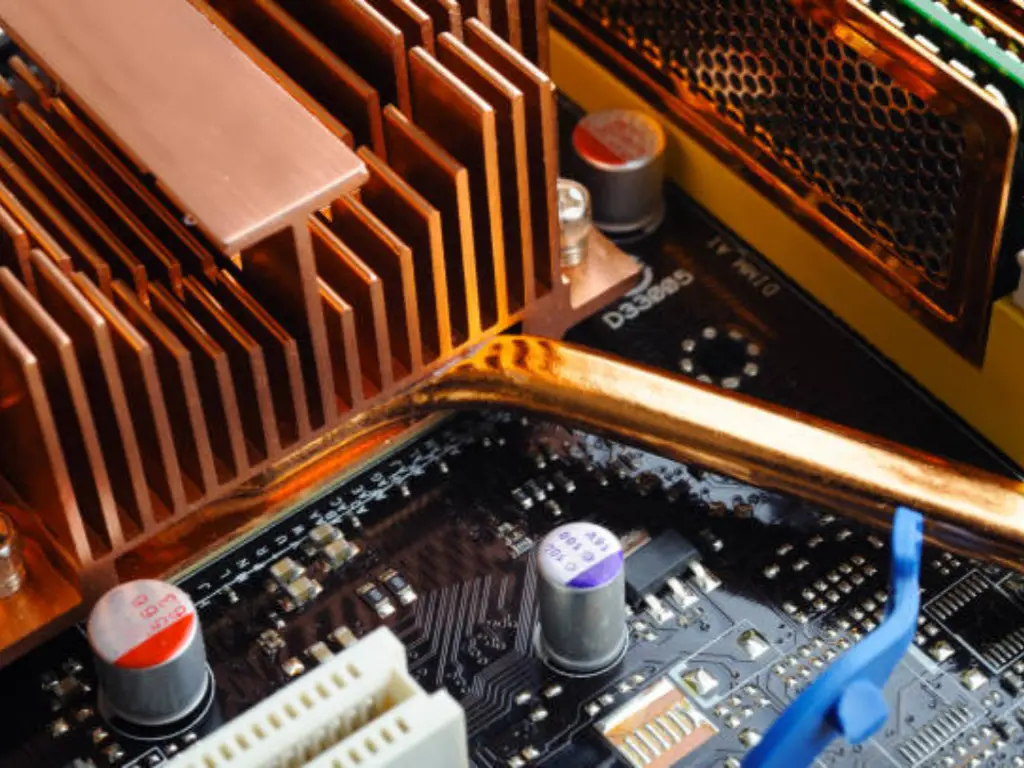

- Heat Sinks: The most common passive cooling element is a heat sink. It serves to enhance the effective surface area through which heat can be dissipated into the surrounding air by convection and radiation. Having a series of pins or fins, heat sinks are usually made of aluminum or copper, and the maximum possible area of contact with the air is maximized. The thermal resistance (°C/W) of a heat sink determines its performance, i.e., the increase in temperature per watt of heat dissipated.

- Heat Pipes and Vapor Chambers: These are very efficient two phase heat transfer devices. A heat pipe is a vacuum-filled, closed tube with a little working fluid (usually water) in it. One end (evaporator) is subjected to heat, which makes the fluid vaporize. This vapor moves to the lower temperature end (the condenser), where it condenses back to a liquid, releasing its latent heat of vaporization. The liquid is then pumped back to the evaporator through a wick structure and the process is repeated. Vapor chambers are flat, planar, and work on the same principle but are able to distribute heat efficiently on a two-dimensional surface.

Active Cooling Solutions

Active cooling solutions apply energy to increase the heat removal rate, and are therefore suitable in high-heat loads.

- Fans and Blowers: These are the mainstay of active air cooling. As quintessential moving parts in thermal solutions, they create forced convection through the movement of a high volume of air, displacing hot air away from heat sinks and other warm components. Axial fans are those that move air in the same direction as the axis of rotation of the fan and are applied in high volume airflow in low-pressure conditions. Blowers, also known as centrifugal fans, force the air in at the center and out at 90 degrees to create greater pressure to force air through more restrictive areas.

- Thermoelectric Coolers (TECs): TECs are solid-state heat pumps also referred to as Peltier devices. The Peltier effect causes the heat to flow across one side of the device to the other when a DC voltage is applied, resulting in a hot side and a cold side. The cold side is then attached to the part that is to be cooled and the hot part should be attached to a heat sink to cool the heat pumped and the heat produced by the device itself.

Advanced/Liquid Cooling Solutions

Advanced and liquid cooling systems are better suited to the most challenging thermal requirements.

- Liquid Cooling: This type of cooling uses a liquid coolant, e.g., deionized water or a dielectric fluid, in a closed loop. The loop is made up of a cold plate attached to the heat source, a pump to circulate the fluid and a radiator (heat exchanger) to cool the heat in the liquid and transfer it to the air. Liquid cooling has much lower thermal resistance than air cooling, and is suitable for high-power CPUs, GPUs, and power electronics.

- Immersion Cooling: In this technique, electronic parts or complete servers are immersed in a dielectric fluid that is thermally conductive and non-conductive to electricity. This offers direct contact between the fluid and the component surfaces and this offers the most efficient possible heat transfer. Two-phase immersion cooling is a method that uses a fluid that boils at the surface of the component and it cools the component by the latent heat of vaporization.

Essential Materials for Electronics Thermal Management

The material selection for building and interfacing any cooling hardware is of critical importance to the performance of the hardware. Essentially, the choice of these materials is the basis of all passive cooling plans.

Thermal Interface Materials (TIMs)

There are no two solid surfaces that are flat. Microscopic air gaps exist at the interface when a heat sink is put on a component. These gaps provide a great deal of thermal resistance since air is a poor conductor of heat. TIMs are substances that are meant to fill these voids and replace the air to enhance thermal transfer. Common types include:

- Thermal Grease: This is a high-performance paste that forms a very thin bond line with the lowest thermal resistance possible.

- Thermal Pads/Gap Fillers: These are easy-to-use solid pads that are used to fill large or irregular gaps, e.g., between a circuit board and a chassis.

- Thermal Tapes & Adhesives: Offer a thermal path and mechanical bond, which is helpful in the attachment of heat sinks without clips or fasteners.

- Phase Change Materials (PCMs): Solid at room temperature to make them easy to apply, they soften or melt at operating temperatures to form a thin, grease-like interface.

Heat Spreaders and High-Conductivity Materials

A heat spreader is a material with higher thermal conductivity that is utilized to spread heat generated at a small, concentrated location to a larger area. This decreases the maximum heat flux, which enables a larger heat sink or other cooling device to be more effective. Usual substances employed in this regard are:

- Copper Plates and Vapor Chambers: This is a traditional and very effective method of heat spreading.

- Annealed Pyrolytic Graphite (APG) Sheets: Have the best in-plane (lateral) thermal conductivity and are used in thin and lightweight applications.

- Boron Nitride: This is a ceramic that has high thermal conductivity and good electrical insulation, thus it is ideal in high-voltage applications.

- Advanced Composites: Engineered materials (e.g., polymer or metal matrix with diamond or ceramic fillers) designed to meet a particular application that requires a special set of thermal, electrical and mechanical characteristics.

| Material Type | Thermal Conductivity (W/m·K) | Flexibility | Typical Applications | Key Features |

| Thermal Grease | 1–10+ | Flexible | Between high-performance chips and heat sinks | Ultra-low thermal resistance; difficult to remove |

| Thermal Pads / Gap Fillers | 1–6 | Flexible | Filling gaps between PCB and chassis | Easy to apply; suitable for large or uneven surfaces |

| Phase Change Materials | 3–6 | Semi-flexible | Interface for solid-state devices | Solid at room temp; forms grease-like layer when heated |

| Copper Plates / Vapor Chambers | 200–400 | Rigid | Heat spreading from concentrated sources | Excellent thermal conduction; structural support |

| Graphite Sheets (APG) | 150–1700 (in-plane) | Flexible | Ultra-thin electronics (phones, tablets) | Lightweight; high in-plane conductivity; bendable |

| Boron Nitride Ceramics | 30–60 | Rigid | Electrically insulated heat paths (high-voltage) | Thermally conductive and electrically insulating |

Real-World Applications: Thermal Management Across Key Industries

Thermal management principles are implemented differently across various industrial applications depending on the constraints and performance demands of these industries.

- Consumer Electronics: The main issue in devices such as smartphones and laptops is to cool a lot of heat inside a very limited volume with no active airflow. Passive cooling methods such as thin vapor chambers and graphite heat spreaders are used by engineers to transfer heat out of the processor to the device chassis, which serves as the ultimate heat sink.

- Automotive Electronics: The automotive market requires high reliability and durability in severe operating conditions. In electric vehicles (EVs), battery packs, power inverters, in-vehicle infotainment systems and Advanced Driver-Assistance Systems (ADAS) produce a lot of heat. These systems are usually equipped with powerful liquid cooling circuits with special radiators to keep operating temperatures stable and safe and to guarantee performance.

- Data Centers and Servers: In data centers, the emphasis is placed on the handling of the huge heat load of the tightly stacked server racks and the optimization of energy consumption and efficiency, which is quantified by Power Usage Effectiveness (PUE). This has prompted a transition away to more advanced approaches to forced-air cooling, such as contained hot/cold aisle designs, direct-to-chip liquid cooling, and large-scale immersion cooling implementations.

- LED Lighting: In solid-state lighting, thermal control is essential because heat has a direct effect on the luminous efficacy (brightness) and life of the LED. Poor heat dissipation leads to color change and lumen deterioration. Thus, LED systems need well-designed heat sinks, which are frequently built into the body of the fixtures, to remove heat off of the LED chip and keep it operating.

- Power Electronics: This division, comprising power supplies, motor drives, and solar inverters, is confronted with the fundamental issue of handling high-power-density products. Such components as MOSFETs and IGBTs may produce localized, high-intensity heat. Thermal management, which may require specialized heat sinks, direct-bonded copper substrates, or even liquid cooling, is needed to avoid component failure and to provide efficient conversion of power.

How Manufacturing Processes Dictate Thermal Performance

A solution to thermal management that works well in simulation may not work well in practice when the physical implementation is incorrect. Thermal performance is directly and significantly affected by the manufacturing processes involved in the production of components, especially the electronic enclosure or chassis. The enclosure is not a protective box, but it is an active part of the overall system.

Accuracy in production is the most important. The dimensions, shape, and location of ventilation cutouts, such as, should be precise to correspond to the airflow models produced in the design stage. The deviations may cause unwanted turbulence or pressure drops, which hinder the airflow. The integrity of an assembly guarantees that the components such as the heat sinks have the correct mounting pressure against the processors which is essential to the success of the TIM. Moreover, the radiative properties of the enclosure can be changed with the selection of the surface finish. An aluminum chassis that has a black anodized finish, e.g., has a much higher surface emissivity, making it more effective at radiating heat to the environment, which is important in passively cooled systems.

Partner with TZR for Thermal Management Excellence

A thermally-efficient design is only as effective as its physical execution. This is where your manufacturing partner’s expertise becomes the critical link to success. TZR is a leading one-stop sheet metal manufacturer, providing integrated services from design to assembly for demanding industries like automotive, medical, and renewable energy.

Our support begins at the earliest stages. TZR’s dedicated Design for Manufacturing (DfM) team helps optimize your design for both thermal performance and manufacturability. We specialize in materials crucial for heat transfer, including aluminum and copper. Our advanced capabilities—from laser cutting complex ventilation patterns and CNC punching to precision bending—are executed with an industry-leading precision of up to ±0.02mm. Furthermore, with over 12 surface treatments like performance-enhancing anodizing, we ensure every enclosure actively contributes to your cooling strategy.

By partnering with TZR, you ensure your design intent is translated into a precisely manufactured, high-performance component that guarantees reliable, real-world thermal performance.

Proactive Design: Simulation and Best Practices for Thermal Management

Thermal management is best and most economical when it is incorporated in the design at the earliest stage. This shift-left approach is based on predictive analysis software, primarily using thermal simulations like Computational Fluid Dynamics (CFD).

The CFD simulation enables the engineer to develop a virtual model of an electronic system and study the movement of heat and air within the system. It is able to forecast the temperature of components, airflow velocity, and pressure drops in different operating conditions. With CFD, designers are able to cycle through layouts, heat sink designs, and fan choices to optimize thermal performance before making the costly decision of physical prototyping. This is a proactive strategy that detects and fixes possible thermal problems at an early stage to avoid expensive redesigns at the last minute and shortens the time to market.

Testing and Validation: Verifying Your Thermal Design

Although simulation is an effective predictive method, physical prototypes must be empirically tested to confirm the design and to verify that it is within specifications. The validation process is done by instrumenting the system to measure important thermal parameters under controlled load conditions.

The most important parameters to be measured are the case temperatures of the critical components (CPUs, GPUs, power FETs), the surface temperatures of the enclosure in the places accessible to the user, and the air temperature at the system inlets and outlets to compute the total heat dissipation.

The most common devices in this process are thermocouples that give precise temperature measurements at a given point and thermal imaging cameras that give a visual representation of the temperature distribution of the entire system and can quickly detect any unexpected hot spots. Airflow rates are measured using anemometers and programmable electronic loads are used to model real-world power consumption. The results obtained in these tests are compared with the results of the CFD simulation to optimize the thermal model and ensure that the product can work safely within its thermal limits.

The Future of Cooling: Emerging Trends in Thermal Management

As the power density of electronics continues to increase, the field of thermal management is constantly evolving. Several emerging trends are shaping the future of cooling technology.

- Generative Design and AI: Artificial intelligence and machine learning algorithms are being used to create highly optimized heat sink designs. These generative design tools can explore thousands of complex geometries that would be impossible for a human to conceive, resulting in structures with superior thermal performance and lower weight.

- Advanced Materials: Research is ongoing into new materials with exceptionally high thermal conductivity. Diamond, with a thermal conductivity five times that of copper, is being developed for use in high-power RF and power electronics applications. Nanomaterials, such as carbon nanotubes and graphene, also show promise for future thermal management solutions.

- Embedded Cooling: Efforts are being made to integrate cooling directly into the semiconductor package. Microfluidic channels etched directly into silicon dies allow for direct-to-chip liquid cooling, offering the lowest possible thermal resistance from the heat source to the coolant.

Conclusion

Thermal management is an indispensable discipline in the design of all modern electronic systems. It is a complex field that demands a holistic approach, integrating the principles of heat transfer physics with a deep understanding of materials, component-level solutions, and system-level design. As this guide is detailed, a successful strategy relies on a proactive design process driven by simulation, validated by empirical testing, and realized through precision manufacturing. As electronic devices continue to push the boundaries of power and miniaturization, the challenges of heat dissipation will only intensify. Consequently, expertise in thermal management will remain a critical factor in creating innovative, reliable, and high-performance electronic products.