Introduction

The procedure of a new vehicle development is one of the most complex processes in the contemporary industry that begins with a spark of an idea and ends with a real object on the open road. It is a monumental orchestration of creativity, engineering rigor, strategic planning, and immense capital. Automotive product development is much more than manufacturing; it is the art of converting the abstract market needs and technological potential into a safe, reliable, and desirable product that will shape the future of automotive companies and manufacturers throughout the vehicle industry. This guide will methodically dismantle this complex lifecycle, providing a clear and detailed roadmap through the initial stages that characterize the journey between concept and market.

What Is Product Development and Why Is It Important

Product development, in any way, is the whole process of bringing a new product to market or revising an existing product. In the automotive industry, the term is further expanded to an enterprise-wide practice that encompasses market research, design, engineering, prototyping, validation, supply chain management, and manufacturing strategy. It is the driver of progress itself to an original equipment manufacturer (OEM) and its tiered suppliers.

Its importance cannot be overstated. Competitive advantage is primarily fuelled by successful product development. It allows a company to respond to the evolving consumer needs, integrate disruptive technologies like electrification that bring new challenges, and comply with an ever-evolving set of global safety and environmental regulations. A poor or inefficient development process will not only result in cost overruns and late launches but also a failure to produce a product that will resonate with the market, which will affect brand reputation and financial viability.

The 7 Foundational Stages of the Automotive Product Development Process

The vehicle development process lifecycle is a sequential, but iterative process. Although particular methodologies can differ, the process always consists of seven stages that are fundamental and have their own goals and obstacles.

Stage 1: Idea Generation

All vehicles start not with a chassis or an engine, but with an idea. This first step is a divergent process that is aimed at casting a broad net of possible product concepts. The sources of inputs are numerous: formal market research on demographic changes, unmet needs, and emerging market trends; competitive analysis comparing rival products; direct customer feedback on pain points and desires; and internal research and development (R&D) on new technological possibilities. The goal is not to come up with an ideal idea, but to create a strong pool of ideas that can be systematically tested against the strategic objectives of the company.

Stage 2: Idea Evaluation and Screening

When a pool of ideas has been created, the process becomes one of analytical reduction. All the concepts are subjected to a strict screening process to establish their viability. This is a filtering process where raw ideas are put to the test against the realities of the business. The most important evaluation criteria:

- Market potential: How big is the market and how fast is it growing?

- Technical feasibility: Can we actually build it using current or attainable technology?

- Resource alignment: Will it fit within our budget and engineering capacity?

- Potential of successful market entry, and brand consistency: Does it fit within our brand identity and promise?

Ideas that do not pass these rigorous standards are systematically discarded, and the organization is free to concentrate its resources on the most promising ideas.

Stage 3: Concept Development and Detailed Planning

A well-screened idea is now a full-fledged vehicle concept. This concept phase is where the high level concept is converted into a detailed business case and product definition. A cross-functional team of designers, engineers, and marketers works together to identify the target market and the specific customer market profile, set key vehicle features and performance targets, and potential new features, develop initial design renderings, and make initial cost estimates. The main deliverable of this phase is a detailed product plan that describes the value proposition of the vehicle, its technical requirements, and financial forecasts and complete vehicle targets. This elaborate plan should be signed off by the top management in a formal target agreement and this necessitates a lot of cooperation and understanding between the departments before the vehicle project can enter the resource-intensive engineering phase.

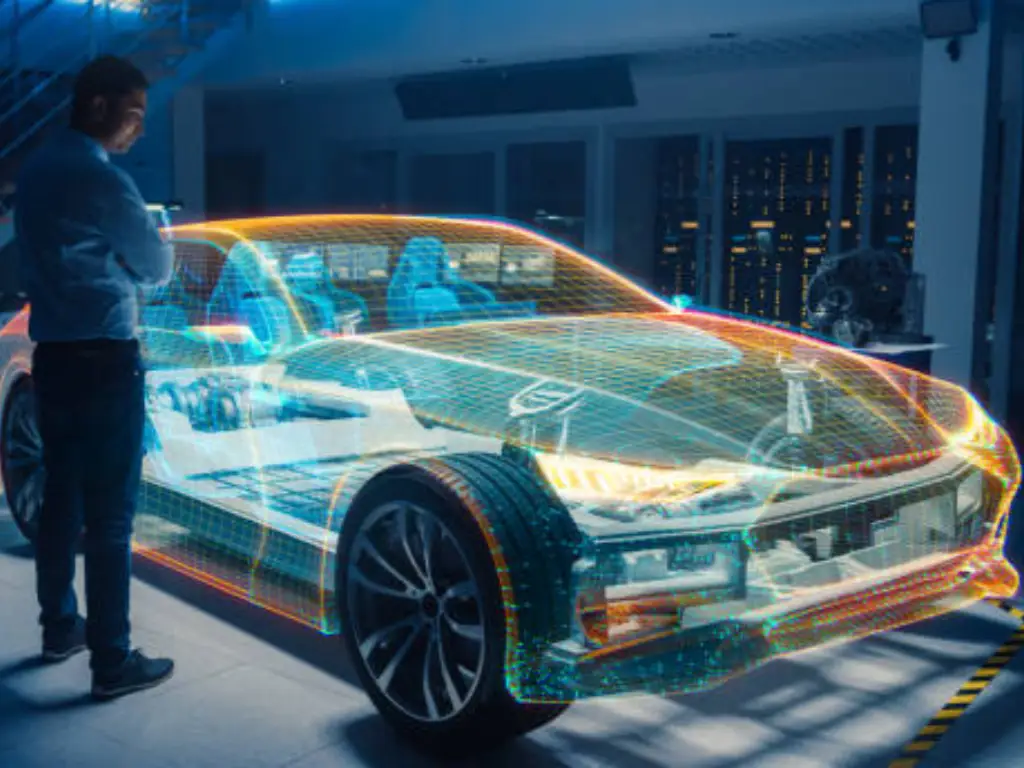

Stage 4: Engineering Design and Prototyping

Once the concept is approved, the project moves to the realm of intense engineering and vehicle design. This is the concept stage where the virtual vehicle is constructed. Technical teams using Computer-Aided Design (CAD) software develop detailed 3D models of all components, systems and assemblies, refining the initial draft that was developed during the concept stage. These computer models are then put through rigorous Computer-Aided Engineering (CAE) simulations to test everything including structural integrity, aerodynamics, crash safety, and thermal management.

After digital validation, the initial physical representations of the vehicle are generated. Prototyping is critical to test form, fit and function in the real world. Preliminary prototypes, commonly referred to as mules, can be based on existing vehicle platforms to test new powertrain or chassis systems. Subsequently, full-vehicle prototypes are built to confirm the entire design. These highly accurate physical components play a vital role in ensuring the structural integrity of the body and the chassis fit as well as the final assembly of trims. They are made using various manufacturing techniques. In numerous core structural and body-in-white parts, precision sheet metal fabrication is essential, as well as traditional CNC machining and advanced additive manufacturing of other specialized parts.

Stage 5: Rigorous Testing and Validation

The physical prototypes are not showpieces; they are constructed to withstand a series of punishing tests that are aimed at proving every detail of the product’s performance and the durability of the vehicle. This validation step is comprehensive. Functional tests make sure that all systems are functioning as intended. Durability tests expose the vehicle to accelerated wear and tear on test tracks and in climate chambers to replicate years of use in the real world. Safety validation is done through controlled crash tests to make sure the vehicle meets or surpasses the high government and internal quality standards (such as those of the NHTSA or Euro NCAP). Each part, including the smallest bracket, is tested to meet all performance requirements and regulatory standards and requirements.

Stage 6: Manufacturing, Production, and Quality Control

After the design has been well tested, attention is turned to industrialization. This step is aimed at preparing the manufacturing process for efficient, repeatable, and high-quality mass production. Engineers use Design for Manufacturability (DFM) concepts to simplify parts to make them easier to manufacture. The procurement department concludes contracts with a chain of suppliers. The jump between a few prototypes and thousands of mass produced parts is enormous, and the capability of a supplier to guarantee the same level of precision and product quality between the prototype and the final part is of utmost importance. Large investments are then made in tooling, including stamping dies and injection molds. Production lines are constructed and put into operation. Strict quality control measures are put in place at each stage of the assembly line to make sure that each vehicle that comes out of the factory is of the exact specifications that were developed and tested during the development stages.

Stage 7: Market Launch and Post-Launch Feedback

The last step is the market entry of the vehicle. This entails a synergistic approach between sales, marketing and distribution to make the launch a success. Dealerships are prepared, advertising campaigns are implemented, and the vehicle is brought to showrooms. Nevertheless, the development process does not stop here. The launch will initiate a critical feedback loop that is critical. The company carefully gathers information on sales, customer surveys, warranty claims, and automotive reviews. This practical feedback is invaluable, and it gives the necessary insights to plan future updates, facelifts, and the next generation of vehicles, and thus the development cycle is restarted with strong life cycle management.

Key Challenges in Modern Automotive Product Development

Although the seven-stage process is a clear roadmap, it has never been more challenging to navigate. The contemporary automotive environment is characterized by a combination of high pressures that all OEMs and suppliers have to surmount. These are the main challenges:

- Aggressive Timelines. The market is now moving at a pace that requires new vehicle launches in as little as 24 to 36 months. Such a drastic shortening of the development cycle demands unparalleled efficiency and does not allow for any mistakes or numerous delays.

- Explosion in Complexity. Cars are no longer mainly mechanical systems; they are now complex software platforms on wheels. The integration of millions of lines of code into infotainment, connectivity and autonomous features is a task that is often larger than traditional engineering challenges.

- Fundamental Technology Shifts. The move to electric vehicles and powertrains across the industry brings with it completely new engineering paradigms. It demands the acquisition of new battery technologies, sophisticated thermal management, and entirely new vehicle designs, all on a steep and unforgiving learning curve.

- Increasing Regulatory Burden. The net of international safety standards, emissions regulations, and compliance requirements is becoming more demanding and complicated every year. Complying with a variety of international regulations with a single vehicle platform introduces considerable cost and complexity to testing and validation.

Best Practices for a Successful Automotive Product Development

In order to maneuver the contemporary development environment, it is not only beneficial, but mandatory to follow a set of core best practices. These practices offer a guideline to handling complexity and speeding the route to market.

- Adopt Technology and Professional Outsourcing. Take advantage of the newest digital technologies in simulation and validation. Outsource strategically to partners who are experts in specialized or capital-intensive processes. This offers access to state-of-the-art capabilities without the huge initial investment, and it maximizes agility and efficiency.

- Make Compliance a Priority on Day One. Incorporate stringent adherence to all safety and environmental regulations into the initial phases of the design process. This proactive strategy is key to preventing expensive late-stage redesigns and disastrous launch delays.

- Commit to Iterative Prototyping. Treat prototypes not as an isolated milestone but as ongoing learning tools. A repetitive process of construction, testing, and improvement enables the early identification of problems and the final product is robust, reliable, and well-validated.

- Choose Established and Trusted Suppliers. A vehicle is as strong as its weakest part. The foundation of a successful product launch is the construction of a supply chain based on credible and quality-oriented partners that will ensure consistency throughout the product launch.

The Bridge from Design to Reality: How TZR Adds Value as Your All-in-One Partner

This is where TZR comes in as your strategic partner in the transition of digital design to the physical reality. We offer a real one-stop shop that transforms manufacturing problems into your competitive edge:

- Expert Engineering at the outset. We are involved in the partnership at the first stage of design. We offer professional DFM (Design for Manufacturability) analysis to make sure your components are optimized to cost, quality, and efficiency before production even starts.

- Uncompromised Precision and Quality. We are dedicated to quality and this is based on a thorough understanding of materials, such as steel, stainless steel, aluminum and copper. We convert your digital designs into perfect physical parts with a manufacturing accuracy of up to +/-0.02mm. This level of excellence is not a promise, but a proven outcome, as demonstrated by our 98 percent product pass rate and quality systems that are beyond ISO standards.

- Flawless Transitioning between Prototype and Production. We have a flexible supply chain that can accommodate single prototypes to large volume runs. This one-supplier model removes the risks and delays of supplier handoffs and provides consistency and a faster time to market.

Contact our specialists today to discuss your next automotive project.

Measuring Success: Key Metrics in Automotive Product Development

Sales figures are not the only measure of the ultimate success of a product development program. A strong set of Key Performance Indicators (KPIs) will give an overview of the efficiency of the process and the effectiveness of the final product.

| Metric | Description |

| Time to Market | Measures the time from official project approval to the start of production, evaluating the speed of development. |

| Development Cost vs. Budget | Tracks the difference between development costs and the initial budget, assessing financial control. |

| Parts Per Million (PPM) | Measures the number of defects in parts supplied per million, serving as a key quality metric. |

| Initial Warranty Claim Rate | Measures the early warranty claim rate after product launch, evaluating initial product reliability. |

| Customer Satisfaction Score | Collects customer feedback to evaluate how well the product met their expectations and experience. |

| Net Promoter Score (NPS) | Measures customer willingness to recommend the product, reflecting overall customer satisfaction and loyalty. |

Shaping the Future: Key Technologies and Trends in Automotive Product Development

The automotive product development lifecycle is about to undergo a major change, and this is due to a strong wave of digital innovation. Three technologies, in particular, will transform efficiency, speed, and design potential:

- The Digital Twin: A Virtual Replica that is Alive. This is the process of developing a dynamic virtual representation of a physical vehicle that is constantly updated with real-world data. This enables engineers to test performance, forecast maintenance, and test software updates on the virtual model during the entire life of the car, significantly reducing the costly physical testing and speeding up post-launch improvements.

- Generative AI: The Co-Pilot of the Engineer. During the initial stages of design, Generative AI can generate and evaluate thousands of optimized component designs, based on predetermined parameters such as weight, strength, and cost, in real time. This transforms the creative process, enabling engineers to find new and extremely efficient solutions that would otherwise not be possible to find by manual iteration alone.

- Additive Manufacturing: Prototype to Production. Also referred to as 3D printing, the technology is rapidly moving beyond rapid prototyping. It is rapidly emerging as a practical way of making complex, lightweight, and customized components to be used in the final production vehicles, allowing on-demand production and radically new designs that cannot be made with conventional tooling.

All these trends are indicators of a future that will be characterized by faster, more data-driven, and more efficient product development.

Conclusion

To sum up, automotive product design and development is a very structured, multi-phased process that requires a combination of strategic vision, engineering accuracy, and impeccable performance. The objective is to traverse vast complexity to deliver a product that is safe, innovative and compelling, through the initial spark of an idea through seven foundational stages of refinement and validation. With the industry moving at an ever-increasing pace, success will more and more be determined not only by internal expertise but also by the quality of strategic partnerships. Selecting professional partners who can perfect the tricky bridge between design and reality is the key to successfully negotiating this path and bringing the next generation of mobility.