Medical Device Materials Explained: Types, Applications and Regulatory Standards

Introduction The advancement of modern medicine is closely tied to the development …

Blank Size

10’ x 20’ (3.05 m x 6.10 m). We can accommodate larger quantities of sheet metal parts upon request.

Lead Time

7-20 days

Sheet Thickness

0.024” – 0.250” typical

General Tolerances

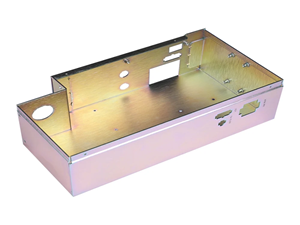

For single planes or flat parts, the tolerance is +/- 0.010 inches on edge-to-edge, edge-to-hole, and hole-to-hole features, as well as +/- 0.010 inches on bend-to-edge/hole features. For multi-planed bent parts, the tolerance is +/- 0.030 inches for hole-to-hole/edge, edge-to-edge, and over-formed parts, with a tolerance of +/- 1 degree for bend angles

Braking (Hydraulic)

10’ length, fingers from 3” – 6”

Punching

2-inch diameter hole capacity, or larger upon request

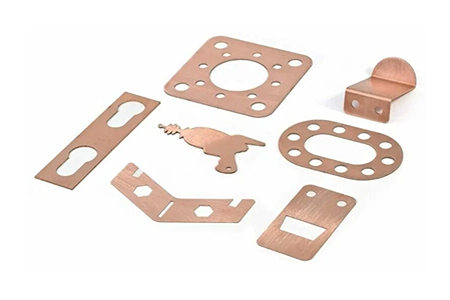

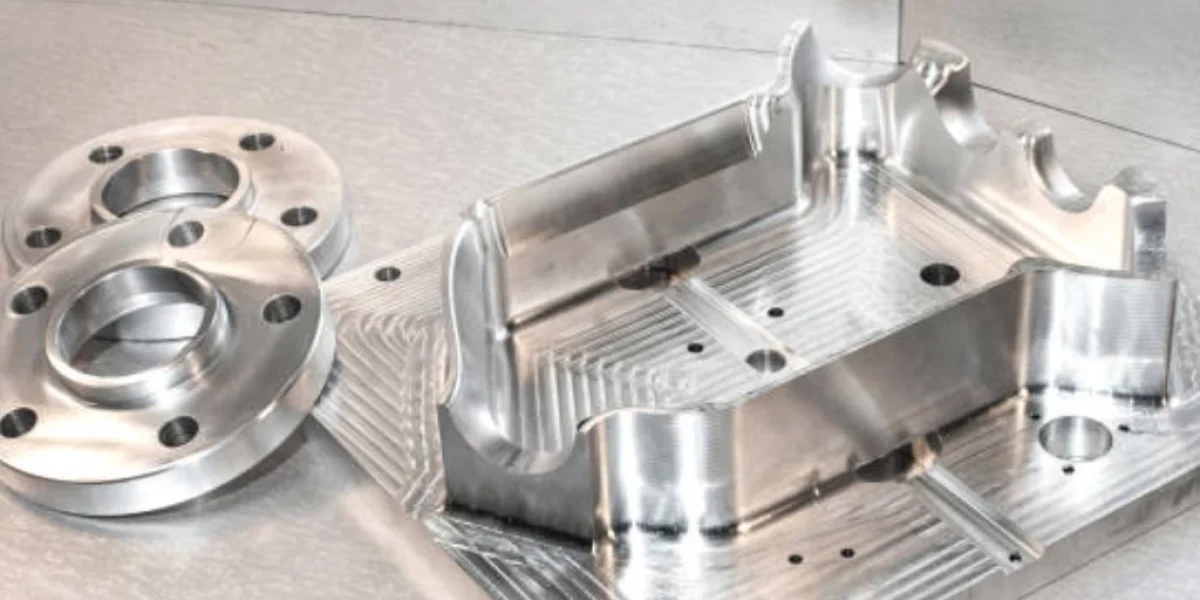

| Material Type | Aluminum | Steel | Stainless Steel | Brass | Copper |

|---|---|---|---|---|---|

| Material |  |  |  |  |  |

| Subtypes | Aluminum 1100-H14 Aluminum 5052-H32 Aluminum 6061 | Steel 1018 (Low Carbon) Steel 1045 (Hot Rolled) Steel A569 AZ55 Galvalume A653 Galvanized 1095 Spring Steel Steel A36 Steel A36, pickled and oiled Steel A366/1008 | Stainless steel 301 Stainless steel 304 Stainless Steel 304 #4 brushed Stainless Steel 304, #8 mirror polish Stainless steel 316/316L Stainless Steel 316, #4 brushed | C27400 C28000 | Copper 101 Copper C110 Copper C110, H02 Copper 260 (Brass) |

| Key Features | Lightweight Corrosion-resistant Easy to process | High strength Wear-resistant Cost-effective | High strength Excellent corrosion resistance Heat-resistant | Good electrical conductivity Corrosion-resistant Wear-resistant | Excellent electrical conductivity Corrosion-resistant High thermal conductivity |

| Applications | Automotive, Aerospace, Electronics, Consumer Goods | Structural Components, Heavy Machinery, Brackets | Medical Devices, Food Processing, Industrial Equipment | Electrical connectors, Mechanical components, Instrumentation parts | Electrical Components, Heat Exchangers |

Recognizing the importance of surface treatment in enhancing both the aesthetics and durability of sheet metal products, we have established an in-house surface treatment workshop. With over 12 sheet metal finishing options available, we ensure comprehensive solutions for every project.

This technique entails propelling sand or other abrasives at high velocity onto sheet metal, imparting a matte texture to the metal parts in preparation for coating.

In this process, a cloth wheel is employed to polish the metal surface, imparting a shiny appearance.

This method entails directly spraying powdered paint onto the metal part, followed by baking it in an oven to create a durable, wear-resistant layer.

Surface painting in sheet metal fabrication involves the precise application of powdered paint onto metal surfaces, creating a visually appealing finish.

Anodizing enhances a component’s rust resistance, concurrently improving surface hardness and durability.

The process involves treating a metal surface to mitigate its susceptibility to corrosion by creating a protective oxide layer on its surface.

Black oxide is a surface treatment method that forms a corrosion-resistant, black oxide layer on metals, improving both aesthetics and durability.

Electroplating is a method of depositing a metal layer onto a substrate using an electrolytic solution, improving appearance, corrosion resistance, and other properties.

Electrolysis is a chemical process that uses an electric current to drive a non-spontaneous reaction, often involving the decomposition of substances.

Laser engraving is a precise technique employing a laser beam to etch or mark designs and text onto materials such as metal, wood, and plastic, providing personalization and customization.

Silk screen printing, or screen printing, utilizes a mesh stencil to apply ink onto surfaces, commonly fabric, enabling the creation of custom designs, logos, and artwork.

Brushing is a surface finishing technique that employs abrasive brushes to achieve a textured or satin-like appearance on metal surfaces, enhancing aesthetics and reducing reflectivity.

Let the sheet metal fabrication experts take care of your product needs. We cater to over 30 countries in Europe and the United States, offering fast and efficient sheet metal manufacturing tailored to your industry requirements. Talk to our experts today and explore the boundless possibilities that our expertise can bring you.

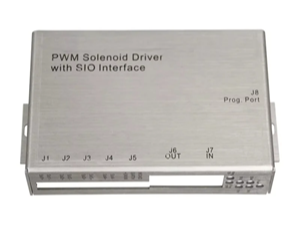

We are proficient in the latest industrial design software for sheet metal design, including CAD and SolidWorks. By aligning with your project goals early, we ensure seamless transitions from design to production.

Our team specializes in fabricating practical sheet metal prototypes, providing you with a firsthand preview of the final product before transitioning to mass production.

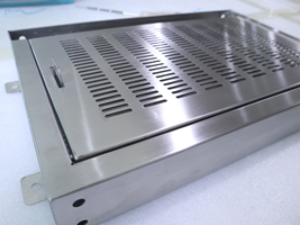

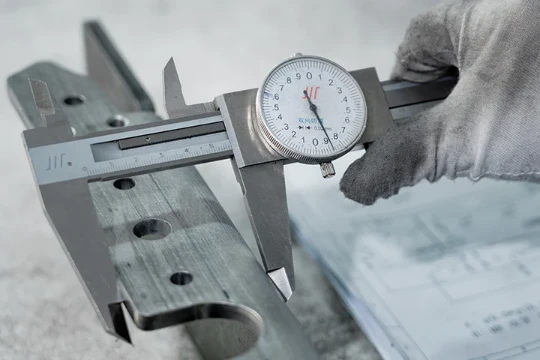

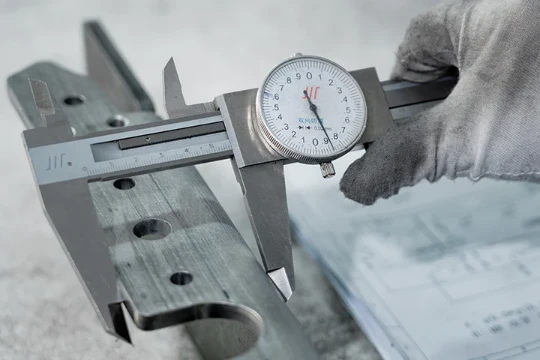

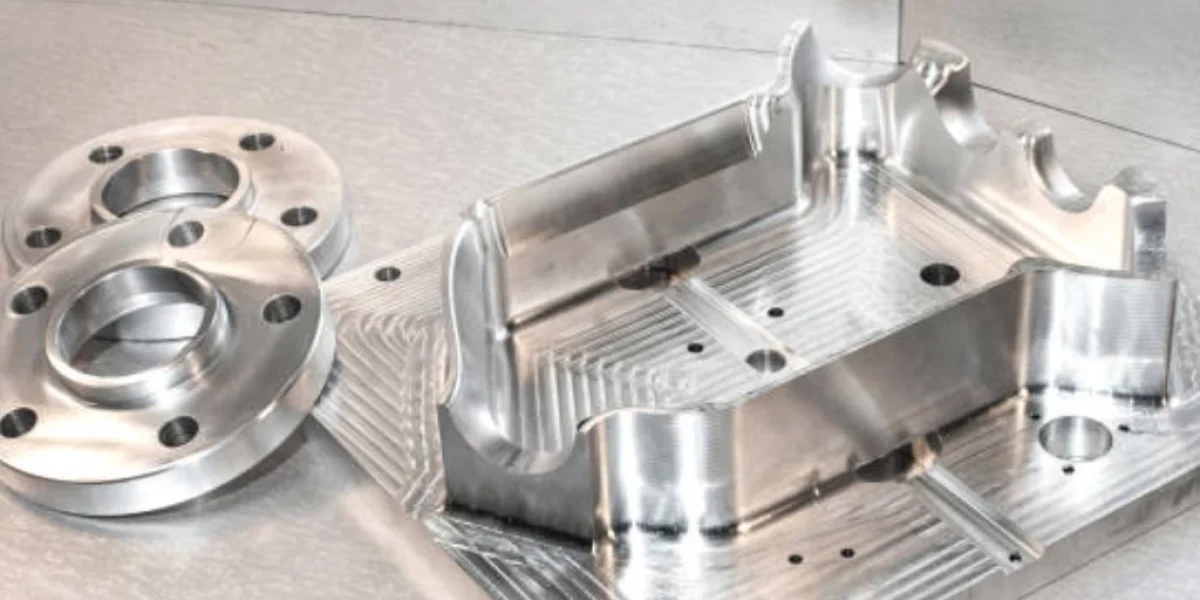

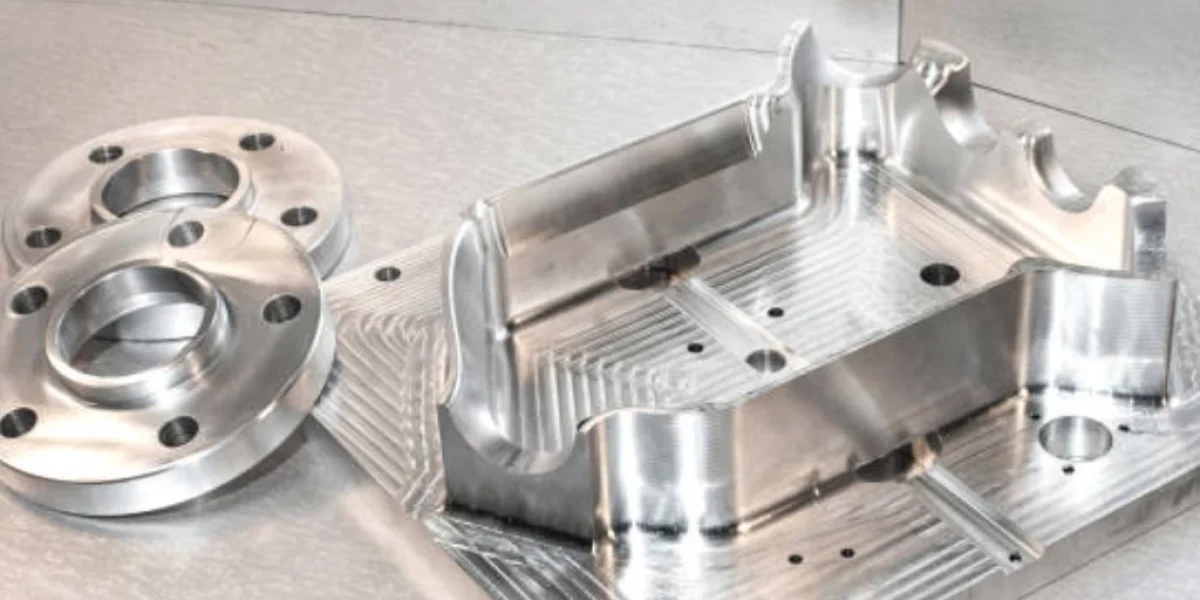

Utilizing the latest sheet metal laser cutting and welding equipment, we ensure precise thickness and dimensions in every sheet metal custom fabrication piece while minimizing wasted time and materials.

We offer a diverse range of in-house surface treatments to finish your sheet metal pieces, including polishing, sandblasting, and electroplating. Whether for aesthetics or performance, we provide consistent, high-quality custom sheet metal work.

With 30 years of experience in sheet metal processing, we solve complex design and manufacturing challenges, providing expert advice and optimizing designs. Our goal is to reduce sheet metal fabrication cost while ensuring top-quality, precise parts.

We ensure full transparency with detailed schedules and timely progress updates, keeping your project on track and avoiding delays in fabricating sheet metal components. This allows quick adjustments to meet deadlines and prevent any disruptions.

At TZR, we manage everything from design to assembly in-house, offering a complete custom sheet metal service that ensures seamless coordination and strict quality control. This minimizes errors, reduces communication costs, and lowers production risks.

Our ISO-certified sheet metal fabrication shop ensures every part meets international standards. With advanced machinery and strict quality control, we guarantee consistent, precise parts that perform reliably over time.

Our strong manufacturing capacity and efficient processes enable us to complete large sheet metal fabrication orders in 7 to 20 days, ensuring rapid delivery and flexibility to meet urgent demands without compromising quality.

Any quality or sheet metal production issues are addressed immediately. If precision requirements are not met, parts are remade, and defects are resolved quickly, ensuring 100% responsibility for the process.

-Over 90% First Pass Yield, 98% Quality Rate-

Our industrial sheet metal fabrication services provide parts made directly from the customer’s 3D CAD model, reducing the likelihood of errors. Proprietary software automates toolpath generation to decrease manufacturing times and reduce costs.

An NDA is not necessary to do business with TZR sheetmetal. When uploading your CAD model to our site, we employ state-of-the-art encryption and anything you upload is protected by confidentiality obligations. For more information, please contact our sales department.

We serve a variety of industries including medical device, automotive, lighting, aerospace, technology, consumer product, and electronics.

We currently have 4 sets laser machine 10 sets bending machine 10 sets drilling machine 2 sets robot bending machine and professional powder coating line With our long history of growth, this number is always changing.

To get a quote for all of our services, simply upload a 3D CAD model on our site. You’ll get an interactive quote within hours with free design feedback. If there are problem areas in the submitted design, our quoting engine provides detailed information on the potential manufacturing issues and suggests possible solutions.

You can get a quotation with 24 hours.

We can accept native SolidWorks (.sldprt) or ProE (.prt) files as well as solid 3D CAD models from other CAD systems output in IGES (.igs), STEP (.stp), ACIS (.sat) or Parasolid (.x_t or .x_b) format. We can also accept .stl files. Two-dimensional (2D) drawings are not accepted.

Yes, we can offer the design service.If you need assistant creating of your idea. Please send email to us and our sales and designers will contact you

Within 2 hours.

Enhanced finishing options and secondary processes are available for sheet metal processes.

We offer FAIs report to you by email.

Introduction The advancement of modern medicine is closely tied to the development …

Introduction Modern electronics has been characterized by two unremitting trends: the growth …

Introduction When designing modern electronics, it is not a choice to control …

Introduction We live in a hyper-connected world where the air is filled …

Introduction: Why EMI Shielding is Non-Negotiable in Modern Electronics The modern era …

Upon receiving the designs, our team of professional consultants will collaborate with you to work on your project.

We will perform a DFM analysis on your design and aim to provide a quote within 2 hours.

Rapid manufacturing will expedite the production of your products, with turnaround times as short as 7 days.

From painting and anodizing to electroplating and more, we have a complete selection of surface finishes, all done in-house.

Strong partnerships with dependable logistics companies ensure your order gets delivered safely and on time.

Copyright © 2023, TZR All rights Reserved. Powered by MML