Sheet Metal Enclosure

- Home

- Sheet Metal Enclosure

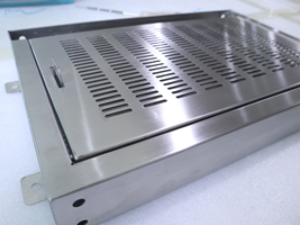

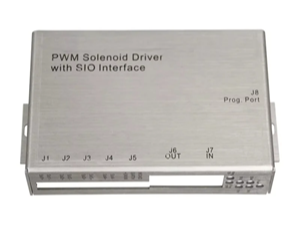

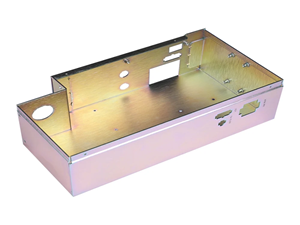

With a decade of expertise in sheet metal enclosure fabrication, we provide one-stop customized enclosure solutions, specializing in designing and producing a range of sheet metal enclosures, including storage containers enclosures, box enclosures, and standard enclosures. All manufacturing is conducted under our ISO 9001 certified processes. Our extensive experience in laser cutting, punching, bending, welding, and more ensures high-quality sheet metal enclosures tailored for diverse applications like electronics and automotive. Leveraging our professional sheet metal workshop and advanced equipment, we deliver high-precision custom enclosures engineered to withstand the harshest conditions. Feel free to upload your design, collaborate with us, and turn your vision into superior sheet metal enclosures.

01

The moment we receive your design, our internal review process begins. Our expert team, led by specialists with 30+ years of experience, conducts a comprehensive technical assessment. This initial review is focused on identifying potential risks and optimization opportunities in areas like material choice, bend radii, and overall manufacturability.

02

Following our initial analysis, we will schedule a dedicated meeting to walk your team through our DFM report. We explain our insights and ask clarifying questions to ensure a shared understanding. This partnership is the most efficient way to co-author a final design that balances function, cost, and manufacturability.

03

Once all revisions are finalized and approved by you, the design is "locked-in" as production-ready. This optimized file becomes the official blueprint for your custom enclosure, ensuring a flawless and consistent manufacturing run.

With a decade of expertise, we specialize in crafting custom sheet metal enclosures tailored to your needs. For electronics, medical devices, or storage solutions, our seasoned team provides professional advice on materials, production methods, surface finishes, logos, and more. Please upload your designs, and we can assist with design and engineering services if needed. Reach out to us today.

TZR technicians excel in various metals, including stainless steel, steel, aluminum, ensuring the ideal materials for your custom sheet metal enclosure fabrication.

TZR specializes in crafting metal lockbox enclosures, aluminum storage box enclosures, metal enclosure boxes for diverse applications, including kitchen and jewelry storage.

TZR excels in diverse manufacturing technologies such as laser cutting, shearing, and tube bending. Our surface finishing options include sandblasting, painting, polishing, and more.

Whether big, small, or medium-sized, TZR has the skills to control precision and prevent deformation in fabricating sheet metal enclosure.

TZR excels in crafting logos for sheet metal enclosures, skillfully employing techniques such as laser engraving, printing, and embossing to showcase your brand with precision and quality.

TZR specializes in customized packaging for sheet metal enclosures, ensuring your products are well-protected and presented with a professional and tailored touch.

With over years of experience, TZR exclusively utilizes the finest materials, expertly matching production methods and surface treatments to each material. Our deep understanding allows us to recommend materials tailored to your product’s usage and environmental needs, ensuring optimal quality and performance.

As an experienced sheet metal enclosure manufacturer, we have assisted customers from various industries in realizing high-quality metal enclosures. If you are looking for a trustworthy metal enclosure manufacturer, look no further. Below are our most frequently requested materials, but if your design requires a specific alloy or a specialty metal like tin, our engineering team is ready to source and fabricate it for you.

| Material Type | Steel | Stainless Steel | Aluminum | Brass | Copper |

|---|---|---|---|---|---|

| Material |  |  |  |  |  |

| Common Grades | Steel 1018 (Low Carbon) Steel 1045 (Hot Rolled) Steel A569 / ASTM A1011 (Hot Rolled) AZ55 Galvalume A653 Galvanized 1095 Spring Steel Steel A36 Steel A36 (Pickled and Oiled) Steel A366/1008 | Stainless Steel 301 Stainless Steel 304 Stainless Steel 304 #4 brushed Stainless Steel 304 #8 mirror polish Stainless Steel 316 / 316L Stainless Steel 316 #4 brushed | Aluminum 1100-H14 Aluminum 5052-H32 Aluminum 6061 | C27400 C28000 | Copper 101 Copper C110 Copper C110, H02 Copper 260 (Brass) |

| Key Characteristics | High Strength Excellent Workability Versatile Finish Required | Excellent Workability Corrosion resistance Strong and durable Easy to Maintain Hygienic and non-toxic | Lightweight Structurally Efficient High Thermal Electrical Conductivity Natural Corrosion Resistance | Premium Appearance Good Electrical Conductivity Application-Specific | Conductive Thermal Highly Formable |

| Typical Applications | Industrial control cabinets Server racks General-purpose boxes | Often used in food, medical, and clean environments | Electronics enclosures Portable instruments Aerospace components | High-end front panels Decorative elements Electrical busbars | High-performance electronics Thermal components |

Equipped with advanced machinery, our meticulous adherence to strict production standards guarantees precision in dimensions and thicker paint coatings. Our skilled craftsmen, with an average of 10 years in sheet metal production, ensure unparalleled expertise.

Possessing advanced laser cutting equipment capable of cutting with precision dimensions.

Professional forming equipment can shape metal materials into appropriate forms.

With advanced bending machinery and robotic bending arms, we can handle complex bending angles, minimizing bend marks.

Our punching capabilities allow for precise hole creation up to 2″ in diameter, and we have the flexibility to process larger dimensions to meet your specific project needs.

Possessing professional automatic deburring machinery, we can efficiently remove burrs from metal products.

To consistently achieve the best results, we employ skilled Mig & Tig professionals with extensive experience in diverse projects.

The thickness standard in the painting industry is 60-100mm, while our internal standard is 80-120mm.

We provide assembly services for your metal enclosures, ensuring precision and cost-effectiveness through seamless integration.

We offer diverse logo options like laser engraving, silk screen printing, and secure packaging for your metal enclosures.

Precision-crafted sheet metal enclosures from TZR find diverse applications across industries, from medical devices to automotive. With a decade of experience in metal enclosure fabrication, we blend our skills and expertise to deliver customized solutions, ensuring the durability and precision of your sheet metal enclosures.

Upon receiving the designs, our team of professional consultants will collaborate with you to work on your project.

We will perform a DFM analysis on your design and aim to provide a quote within 2 hours.

Rapid manufacturing will expedite the production of your products, with turnaround times as short as 7 days.

From painting and anodizing to electroplating and more, we have a complete selection of surface finishes, all done in-house.

Strong partnerships with dependable logistics companies ensure your order gets delivered safely and on time.

Copyright © 2023, TZR All rights Reserved. Powered by MML