Introduction

Germany has always been a powerhouse of engineering excellence, and this tradition is deep rooted in the sheet metal fabrication firms. German manufacturers provide the best services in the world, with laser cutting and CNC machining, powder coating and full assembly, the precision is uncompromising. This article highlights 10 of the best sheet metal fabrication companies in Germany, companies that have integrated the latest technology with the rich craftsmanship to meet the demands of complex projects with tight lead times and tolerances. This list will have something to offer whether you are sourcing custom parts, or high-quality stainless steel components.

| Company | Year Founded | Location |

| BVS Blechtechnik GmbH | 1989 | Böblingen |

| Anton Lippert GmbH | 1962 | Dillingen a.d. Donau |

| Eirenschmalz GmbH | 1990 | Schwabsoien |

| de Crignis GmbH | 1868 | Augsburg |

| HENKE Industrielle Blechbearbeitung | 1989 | Nationwide (Germany) |

| G.W.P. Manufacturing Services AG | 1996 | Teltow |

| ZVK GmbH | 1963 | Teisnach |

| KURIOS Laserprodukt GmbH | 1994 | Hamburg |

| Otto Klostermann GmbH | 1884 | Castrop-Rauxel |

| G. Schürholz GmbH | 1905 | Plettenberg |

Top Sheet Metal Fabrication Company in China – TZR

Founded: 2013

Headquarters: Dongguan, China

Quality Certificate: ROHS, ISO9001:2015, TÜV

Worked Materials: Aluminum, steel, stainless steel, copper, brass

Application Market: Automotive, Medical Devices, 3D Printing, Industrial Equipment, Server Enclosures

Service Region: Germany, Global

Key Services: Sheet Cutting, Plasma Cutting, Tube Bending, Laser Cutting, Laser Tube Cutting, Metal Laser Engraving, Precision Sheet Metal Fabrication

Specific Description:

TZR, headquartered in China, is a premier sheet metal fabrication company known for its cost-effective production capabilities and expertise in handling high-volume orders. Specializing in industries such as automotive, medical devices, 3D printing, and renewable energy, TZR offers comprehensive services from design and prototyping to mass production.

With over 11,000 square meters of production space and a team of 120 skilled professionals, TZR is proficient in working with a variety of materials, including steel, stainless steel, aluminum, and copper. The company utilizes advanced manufacturing techniques such as laser cutting, CNC punching, precision bending, welding, and surface treatments. Their DFM (Design for Manufacturability) engineering support, fast 2-hour quoting, and over 98% yield rate make them a highly reliable partner.

What sets TZR apart is its ability to serve both small-batch prototyping and large-scale production with equal efficiency, offering competitive, customized pricing solutions. Backed by a strong supply chain and strict quality control that goes beyond ISO standards, TZR has earned the trust of clients in over 30 countries.

Founded by Gary, a former senior professional at Foxconn with 14 years of experience, TZR blends global-quality manufacturing with agile service, delivering Foxconn-level quality without the Foxconn-scale commitment.

For businesses seeking a reliable, efficient, and globally competitive sheet metal fabrication partner in Asia, TZR stands out as a strategic choice.

BVS Blechtechnik Gmb

Founding Year: 1989

Headquarters: Böblingen

Quality Certificate: ISO 9001

Application Market: Electronics, medical, telecommunications, and industrial machinery

Service Region: Primarily Germany and wider Europe

Key Services: Precision sheet metal parts, surface finishing, enclosure fabrication, final assembly with electronics

Specific Description: BVS Blechtechnik GmbH is the embodiment of precision sheet metal fabrication firms. Based in its state-of-the-art facility in Bollingen, the company has established its reputation for high-end automation, using a state-of-the-art fleet of machinery to manufacture everything, including complex custom parts and intricate brackets. BVS has over 300 employees and is a specialist in the manufacture of fine sheet metal components and enclosures that require perfect form and finish. Their real differentiator is that they can incorporate electronics into fabricated assemblies, providing clients not only with mechanical components but with almost plug-and-play subassemblies.

Customers in industries such as medical equipment and industrial automation appreciate the high production tolerances and ISO-certified quality systems of BVS. Their internal operations are flexible- you can be starting a prototype or ramping up to mid-volume production. They are able to provide complex projects with impressive turnaround times due to digital CAD/CAM integration and the latest equipment. Their strategy has made them a one-stop shop to anyone who requires custom fabrication without any compromise on quality.

Anton Lippert GmbH

Founding Year: 1962

Headquarters: Dillingen a.d. Donau

Quality Certificate: ISO 9001

Application Market: Control technology, machinery, electronics

Service Region: Germany, Austria, Switzerland

Key Services: Sheet metal housings, control cabinets, foam gasket application, CAD-supported design

Specific Description: Anton Lippert GmbH is a company that has been dealing with metal housings, control cabinets, and machine enclosures for more than 60 years. Being a full-system supplier, they not only produce parts but also offer the clients the complete service, including design and delivery. Their niche? Custom enclosure manufacturing with options such as built-in sealing foam with state-of-the-art dosing technologies. Lippert focuses on collaboration that is consultation-intensive, with each build being customized to the specifications of a client.

The company has a highly skilled workforce of 180 professionals, and it uses modern CAD/CNC systems to do rapid prototyping and serial production efficiently. They are very useful in the automation and electronics industries due to their thermal management, structural rigidity, and EMI shielding. Having an impressive capability to manufacture both one-offs and batch runs, Anton Lippert is one of those sheet metal fabrication companies that are not only good at precision, but also at clever engineering collaborations.

Eirenschmalz GmbH

Founding Year: 1990

Headquarters: Schwabsoien

Quality Certificate: ISO 9001, EN 1090, EN 3834, ISO 50001

Application Market: Mechanical engineering, agriculture, medical devices

Service Region: Germany and international markets

Key Services: Laser cutting, tube processing, CNC machining, assembly, design assistance

Specific Description:

If you are in search of a full fabrication partner, then you should remember the name Eirenschmalz GmbH. They span the whole gamut, including CAD-aided design to packaged and shipped components. The company specializes in sheet and tubular metal components and is renowned for having the most advanced laser cutting and tube laser systems that allow the creation of highly complex geometries with pinpoint accuracy.

What is actually strong about them is their flexibility. You may be developing a new prototype or you may be considering scaling up into volume production. Eirenschmalz has the tools and expertise to take you through the process. They have approximately 200 employees and a vertically integrated workflow, which minimizes the necessity of outsourcing, which is directly converted into short lead times and stable quality. It is one of the few precision sheet metal fabrication companies that can easily fill the gap between the product idea and final delivery, all at competitive prices.

de Crignis GmbH

Founding Year: 1867

Headquarters: Augsburg, Germany

Quality Certificate: ISO 9001

Application Market: Electronics, medical devices, mechanical engineering

Service Region: Germany and broader Europe

Key Services: Customized enclosures, sheet metal cladding, complex assemblies, system integration

Specific Description:

De Crignis GmbH is an old sheet metal fabrication company founded in 1867 in Augsburg, Germany. It specializes in custom enclosures, sheet metal cladding, and assembled modules and serves industries that require high precision, fine surface finishes, and complex geometries.

The company provides full-service capabilities including development, CAD design, bending, laser cutting, powder coating and mechanical assembly. One of the distinguishing factors is the ability to integrate systems, both functional and electrical components, into housing systems.

Having a staff of approximately 150 professionals and state-of-the-art fabrication technology, de Crignis is a leader in prototyping and small to medium-scale production with tight tolerances and short lead times. They have a focus on engineering quality and flexibility that makes them an outstanding precision sheet metal fabrication company in Germany.

HENKE Industrielle Blechbearbeitung

Founding Year: 1989

Headquarters: Nationwide (Germany)

Quality Certificate: ISO 9001

Application Market: Industrial systems, automation, electrical systems

Service Region: Germany and surrounding countries

Key Services: Laser cutting, punching, forming, welding, surface treatment, assembly

Specific Description: HENKE Industrielle Blechbearbeitung is a well-integrated sheet metal fabrication company that specializes in high-precision, turnkey manufacturing solutions. From design to mass production, they deliver comprehensive fabrication services enhanced by strong logistics and a robust quality management system. Their strength lies in their ability to manage diverse materials and complex part geometries, underpinned by CAD-driven processes and high-efficiency PPS systems.

Their integrated operations allow them to fulfill custom fabrication needs, even when customers require full assembly and surface finishing such as powder coating. HENKE’s structure supports rapid response times and agile project execution, making them highly competitive in industries like automation and power distribution. With their strong emphasis on sustainability and long-term process optimization, HENKE represents the kind of progressive sheet metal company that combines tradition with innovation.

G.W.P. Manufacturing Services AG

Founding Year: 1996

Headquarters: Teltow

Quality Certificate: ISO 9001

Application Market: Consumer electronics, industrial devices, mechanical systems

Service Region: Germany, Europe, and select international clients

Key Services: Sheet metal processing, CNC, die casting, injection molding, surface treatment

Specific Description: G.W.P. AG takes the concept of one-stop manufacturing to another level. More than just a sheet metal fabrication company, they blend multiple production disciplines—like CNC milling, injection molding, and pressure die casting—under one roof. This cross-functional capability is a significant asset for clients who require hybrid part construction or consolidated sourcing for complex assemblies.

With a focus on short lead times, flexibility, and rapid prototyping, G.W.P. serves a broad industrial base from its facility near Berlin. Their deep experience in integrating materials like stainless steel and engineered plastics means they can address a wide range of specifications, from aesthetics to structural performance. They are particularly skilled at managing small- and medium-volume runs, making them ideal for emerging tech firms, startups, or companies looking to scale new products with agility.

ZVK GmbH

Founding Year: 1963

Headquarters: Teisnach

Quality Certificate: ISO 9001

Application Market: Data centers, building infrastructure, telecom

Service Region: Primarily Germany, affiliated with Rohde & Schwarz global operations

Key Services: Sheet metal processing, cabinet and enclosure assembly, screen printing, digital labeling

Specific Description: ZVK GmbH is a key part of Rohde & Schwarz’s business and specializes in high-end sheet metal parts of telecom infrastructure and industrial enclosures. Their contribution to the provision of high-quality electrical cabinet systems makes them one of the few precision sheet metal fabrication companies that are highly involved in the supply chain of mission-critical infrastructure.

They have facilities that provide sophisticated printing, labeling, and surface finishing, so they can do more than structural fabrication and provide fully finished and branded parts. They have state-of-the-art equipment, which, combined with scalable workforce support of more than 2,000 employees at the Teisnach site, guarantees reliability and high throughput. The quality assurance and traceability systems of ZVK are very strong and they meet the high standards of the global OEMs.

KURIOS Laserprodukt GmbH

Founding Year: 1994

Headquarters: Hamburg

Quality Certificate: ISO 9001

Application Market: Medical technology, aerospace, mechanical engineering, electronics

Service Region: Germany and Europe

Key Services: 2D/3D laser cutting, laser welding, HSC milling, bending, stamping, surface treatment, assembly

Specific Description: KURIOS Laserprodukt GmbH is one of the most specialized precision sheet metal fabrication companies in Germany, especially in laser processing. They are strong in working with difficult geometries, thin and thick metal types, and materials, including steel and stainless steel, aluminum, and even titanium. This ability makes them an ideal partner to high specification industries like medical, aerospace and electronics, where tolerances are stringent and quality is not negotiable.

The 2D and 3D laser cutting technology, laser welding and high-speed milling (HSC) of the company enable them to provide smooth transitions between design and production. In addition, KURIOS has incorporated surface finishing and component assembly in its services, thus being a complete end-to-end provider. They have a highly trained workforce, sophisticated equipment and modular production planning that guarantees quick turnaround and high quality even on small to mid-size production runs. KURIOS has more than 130 professionals and an innovation-based culture that keeps challenging the limits of what can be done in high-precision sheet metal fabrication.

Otto Klostermann GmbH

Founding Year: 1884

Headquarters: Castrop-Rauxel

Quality Certificate: ISO 9001

Application Market: Shipbuilding, power generation, heavy machinery

Service Region: Germany and selected international markets

Key Services: Thick sheet metal processing, plasma cutting, cold forming, large welded structures

Specific Description: With a history dating back to the 19th century, Otto Klostermann GmbH is one of Germany’s most experienced sheet metal fabrication companies—and a specialist in large and thick-gauge metal work. They focus on cold forming, plasma cutting, and complex welding constructions, making them ideal for clients in the energy, maritime, and heavy engineering sectors.

Unlike many other fabricators, Klostermann’s core competency lies in the processing of massive sheets and oversized components, often requiring custom tool paths and unique heat treatments. Their engineering team is capable of designing and implementing solutions for large-scale challenges that involve heavy-duty stress tolerances and high thermal loads. Their legacy of technical excellence is matched by continuous investment in modern forming and cutting technology. With approximately 150 employees, Otto Klostermann GmbH has built a reputation for delivering durable, tailor-made solutions to clients with some of the most demanding applications in metal engineering.

G. Schürholz GmbH

Founding Year: 1905

Headquarters: Plettenberg

Quality Certificate: IATF 16949, ISO 9001, ISO 14001, ISO 45001

Application Market: Automotive, electronics, household appliances, medical

Service Region: Germany, EU, global tier-1 suppliers

Key Services: Precision stamping, deep drawing, laser cutting, bending, welding, surface finishing, tool making

Specific Description: G. Schurholz GmbH is a pillar in the German precision sheet metal fabrication industry, especially in the segment of high-volume and complex metal component production. The company supplies to industries that are active worldwide such as automotive and electronics, where it provides millions of parts annually with extreme dimensional accuracy and surface integrity. They are very automated in production, with in-house tools and die manufacturing, and are among the highest standards in the world metalworking industry.

Their capability to handle deep drawing, stamping, and resistance welding in seamless production processes is one of their greatest differentiators. This and IATF 16949 certification enable them to achieve high-quality and compliance standards of large OEMs. Also, Schurholz uses digital twin technology and predictive maintenance systems to guarantee uptime and efficiency. Having approximately 250 employees and more than a century of experience, they are a perfect example of how a traditional sheet metal workshop can become a high-performance metal fabrication company with a reputation of a world-class brand.

Key Criteria for Choosing Your Partner

The choice of a sheet metal fabrication partner is a very important decision that can have a huge effect on project schedules, product quality, and cost. In addition to the cost per part, several aspects should be considered to make the partnership successful and long-term.

First, Experience and Expertise are the key. A fabricator that has a history of success in your particular industry will have an inherent knowledge of the applicable standards, material needs, and typical issues. Their experience can be turned into useful design-for-manufacturability (DFM) input, resulting in more efficient and cost-effective solutions.

Second, Quality of Work and Precision supported by a strong quality management system is non-negotiable. Ask them about their certifications, including ISO 9001, and their internal quality control processes. This covers all the way to inspection of materials on arrival, in-process inspection and final inspection reports. The capability to maintain tight tolerances is a major indicator of a high-quality operation.

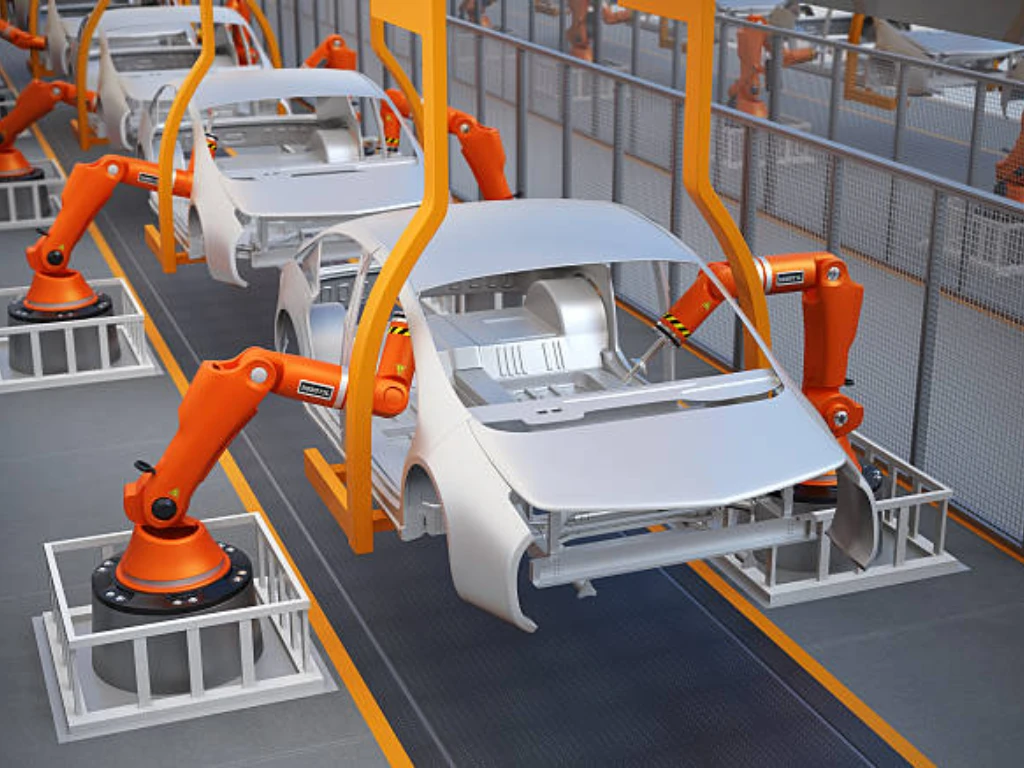

Third, assess their Equipment and Technology. A contemporary machine park with the latest CNC machines, powerful fiber lasers, and robotic welding cells is a sign of precision, efficiency, and the capacity to work on complex projects. High technology usually results in shorter lead times and better finishes.

Fourth, On-Time Delivery and Project Management are essential in keeping your own production schedules. A good partner will possess an open and sound project management system, which will offer clear communication and delivery schedules. This can be a great strength in their capacity to take rush orders or last-minute scope changes.

Last but not least, a good working relationship is based on Customer Service and Communication. Select a fabricator who is responsive, transparent in their quoting and who is willing to be collaborative. A partner who updates you on the production process and is easily accessible to answer questions will be very valuable in the long term.

Germany’s Sheet Metal Industry: Navigating Unique Pressures & Opportunities

Core National Drivers: Industry 4.0 & Energiewende

The German sheet metal industry’s evolution is uniquely shaped by two national strategic pillars. Firstly, the “Industry 4.0” initiative mandates a deep integration of automation, IoT, and AI, pushing firms to maintain a global technological lead. Secondly, the ambitious Energiewende (energy transition) policy drives the sector towards sustainable practices, such as adopting “green steel” and circular economy principles.

The High-Cost Dilemma

While these drivers foster innovation, they also contribute to a significant challenge: a high-cost operating environment.

High Energy Prices: A direct consequence of the Energiewende, Germany’s industrial energy costs are among the highest in Europe, directly impacting the profitability of this energy-intensive sector.

The “Made in Germany” Premium: Upholding the world-renowned “Made in Germany” quality standard requires substantial and continuous investment in precision technology, R&D, and a highly compensated workforce protected by robust labor laws.

Intensifying Market and Labor Pressures

The industry faces a two-front battle:

Fierce Global Competition: Competitors are rapidly improving in quality while maintaining a significant price advantage. This puts direct pressure on Germany’s high-cost, high-quality business model.

Chronic Skilled Labor Shortage: An aging population and a declining interest in manufacturing careers have created a severe shortage of qualified technicians and engineers. This shortage hampers the ability to operate and maintain the very advanced machinery required for Industry 4.0.

Strategic Response: A Focus on High Value

In response to these challenges, German firms are not competing on price. Instead, they are reinforcing their core strengths by:

Focusing on High-Value-Added Services: Moving beyond simple fabrication to offer complex, integrated system solutions.

Leveraging Engineering Excellence: Specializing in sophisticated components and assemblies that require a high degree of technical expertise.

Doubling Down on Quality: Using the “Made in Germany” brand as a key differentiator for customers who prioritize reliability, precision, and long-term value over initial cost.

Conclusion

Germany’s leading sheet metal fabrication companies represent a benchmark in quality, innovation, and engineering depth. From BVS Blechtechnik’s high automation, to G. Schürholz’s volume production excellence, these companies exemplify what modern precision sheet metal fabrication companies should offer: technological diversity, commitment to quality, and client-centric flexibility. Whether you’re sourcing for high-mix low-volume or mass production, this list provides a strategic starting point for identifying your next fabrication partner.